Questions? Please Contact Your Local Manufacturer’s Representative

3-51

SECTION 3

Hydronic-PURE-Control-UserManual-211214

CONTROL MENUS

!

WARNING

All information in this addendum is

for reference and guidance purposes,

and does not substitute for required

professional training, conduct, and strict

adherence to applicable jurisdictional/

professional codes or regulations.

Follow all proper lockout/tagout

procedures for service. Before beginning

any service, ensure area is free of

combustible materials and other dangers.

In order to meet warranty conditions,

ensure all appropriate maintenance

activities are performed.

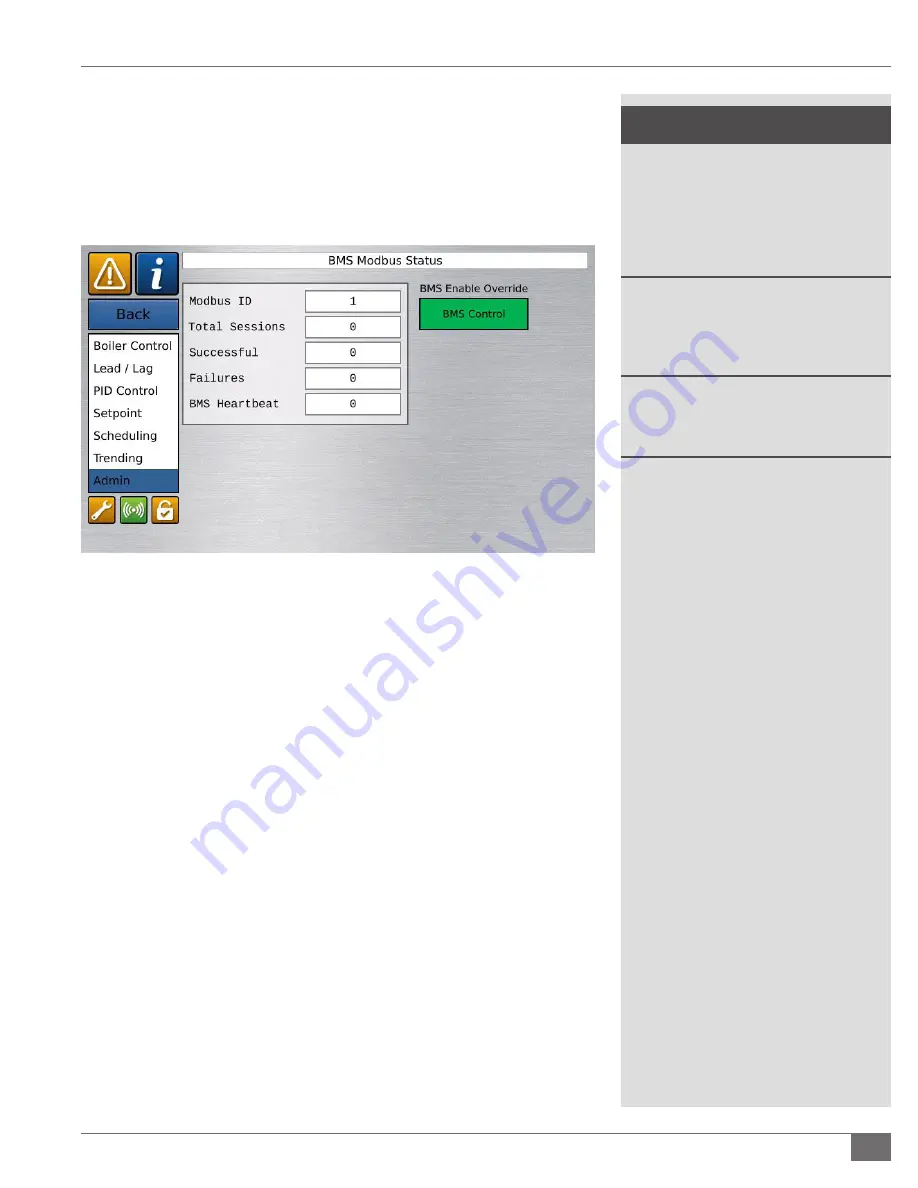

BMS Network Status

Shows communication and status between the control and the BMS or other

connected Modbus device.

BMS Enable Override

provides a way to satisfy the BMS enable (Network or Dry

Contact) without needing to send a signal. This can be used if switching quickly to

Local/Standalone control or Troubleshooting purposes.

It is acceptable to wire a BAS Enable/Disable to one boiler Customer Connections

only and share this contact status over Universal Data to the Lead/Lag network.

Be advised that, per the intended Sequence of Operation, if the network is

dropped or lost, or the boiler sharing this parameter is powered off, the other

boilers will need to have the BMS Enable/Disable override button pressed to be

enabled for operation.

For situations where this is not the intended behavior, alternately the BAS Enable/

Disable can be wired in parallel across the contact of each boiler in the Leag/

Lag network. BMS communication can also be established with each respective

boiler for individual control over the BMS network (Modbus/Bacnet)