93

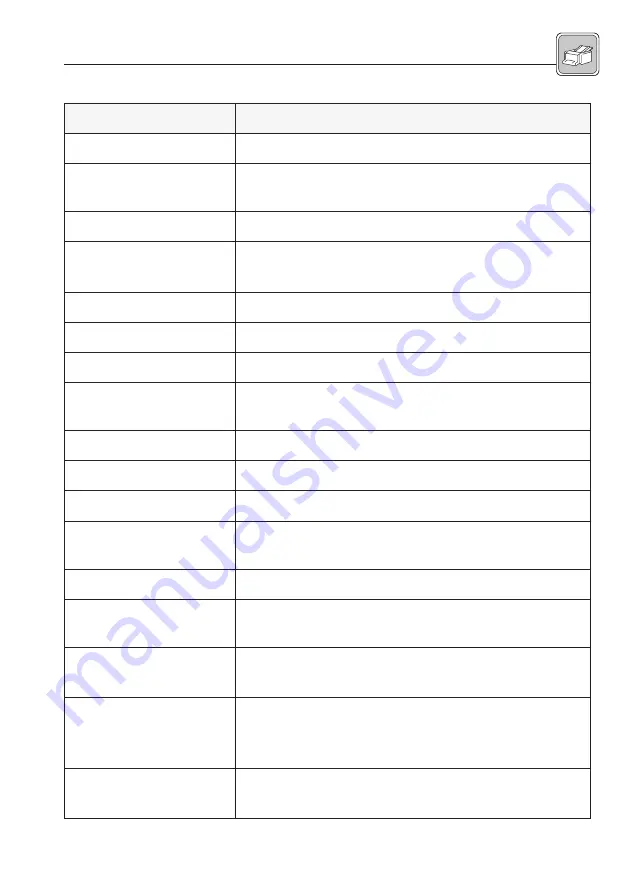

Modules – Feeder / Folding feeder

s

l

o

r

t

n

o

C

n

o

i

t

c

n

u

F

1

s

li

a

r

e

d

i

u

G

s

e

d

i

u

g

r

e

p

a

P

2

s

w

e

r

c

s

d

e

l

r

u

n

K

)

w

o

l

e

b

(

s

li

a

r

e

d

i

u

g

k

c

o

L

3

l

e

n

a

p

l

o

r

t

n

o

C

s

r

o

r

r

e

d

n

a

s

u

t

a

t

s

g

n

it

a

r

e

p

o

s

w

o

h

s

,

s

t

u

p

n

i

s

l

o

r

t

n

o

C

4

t

e

k

c

o

p

g

n

i

d

l

o

F

r

o

t

c

e

l

e

s

)

s

(

t

e

k

c

o

p

g

n

i

d

l

o

f

s

l

e

c

n

a

c

/

s

e

t

a

v

it

c

A

-

d

l

o

f

o

n

=

d

e

s

s

e

r

p

n

o

t

t

u

B

-

5

d

a

e

h

g

n

it

a

r

a

p

e

S

k

c

a

t

s

m

o

r

f

s

t

e

e

h

s

e

l

g

n

i

s

s

w

a

r

D

6

r

e

v

e

L

d

a

e

h

g

n

it

a

r

a

p

e

s

s

e

s

i

a

r

/

s

r

e

w

o

L

7

l

e

e

h

w

l

o

r

t

n

o

C

d

e

e

p

s

g

n

it

a

r

e

p

o

s

t

e

S

8

r

e

t

n

u

o

c

t

e

s

e

r

P

)

l

a

n

o

it

p

o

(

d

e

s

s

e

c

o

r

p

e

b

o

t

s

t

e

e

h

s

f

o

r

e

b

m

u

n

e

h

t

s

t

c

e

l

e

s

e

r

P

9

b

o

n

K

e

t

a

g

r

o

t

a

r

a

p

e

s

s

t

s

u

j

d

A

0

1

y

a

l

p

s

i

D

s

e

d

o

c

r

o

r

r

e

d

n

a

s

n

o

it

c

n

u

f

s

y

a

l

p

s

i

D

1

1

s

D

E

L

s

n

o

t

t

u

b

l

a

u

d

i

v

i

d

n

i

f

o

s

u

t

a

t

s

w

o

h

S

2

1

d

e

e

f

-

d

e

y

a

l

e

D

n

o

t

t

u

b

)

d

e

e

f

t

e

e

h

s

e

l

p

it

l

u

m

(

d

e

e

f

s

y

a

l

e

D

3

1

n

o

t

t

u

b

F

F

O

/

N

O

F

F

O

/

N

O

r

e

d

e

e

f

g

n

i

d

l

o

f

/

r

e

d

e

e

f

s

n

r

u

T

4

1

d

l

e

if

d

e

i

p

u

c

c

O

n

o

t

t

u

b

d

l

e

if

d

e

i

p

u

c

c

o

o

t

s

d

e

e

F

5

1

n

o

t

t

u

b

d

e

e

f

-

e

l

g

n

i

S

s

e

s

o

p

r

u

p

t

s

e

t

r

o

f

e

g

a

p

e

l

g

n

i

s

s

d

e

e

F

-

e

t

f

a

e

g

a

p

a

s

d

e

e

F

-

r

e

e

f

y

tl

u

a

f

“

”

d

6

1

n

o

t

t

u

b

t

r

a

t

S

e

u

l

a

v

e

c

n

e

r

e

f

e

r

d

n

if

o

t

t

e

e

h

s

n

e

o

s

d

e

e

F

-

e

u

l

a

v

e

c

n

e

r

e

f

e

r

s

m

r

if

n

o

C

-

tl

u

a

f

g

n

i

r

a

e

l

c

r

e

t

f

a

n

o

it

a

r

e

p

o

c

it

a

m

o

t

u

a

s

e

m

u

s

e

R

-

7

1

n

o

t

t

u

b

p

o

t

S

n

o

it

a

r

e

p

o

c

it

a

m

o

t

u

a

s

t

p

u

r

r

e

t

n

i

/

s

d

n

E

-

e

u

l

a

v

e

c

n

e

r

e

f

e

r

s

e

t

e

l

e

D

-

Summary of Contents for KS 4000 OL

Page 6: ...8 Operator Manual KS 4000 OL OLC...

Page 8: ...10 Operator Manual KS 4000 OL OLC...

Page 42: ...44 Operator Manual KS 4000 OL OLC...

Page 82: ...84 Betriebsanleitung KS 4000 OL OLC 7 5 Folder 1 2 3 4 4 5 7 6...

Page 86: ...88 Operator Manual KS 4000 OL OLC 7 7 Conveyor 1 4 5 2 3 6 7...

Page 98: ...100 Operator Manual KS 4000 OL OLC 7 10 Sealer 2 1 3 4 8 9 10 5 7 6 6 5 1...