321023

92

13

SEALED SYSTEM SERVICE PROCEDURES

13.1 Service

Equipment

Listed below is equipment needed for proper servicing of HFC134a systems. Verify equipment is

confirmed by manufacturer as being compatible with H FC134a and ester oil system.

Equipment must be exclusively used for HFC134a. Exclusive use of equipment only applies to italic

items.

•

Evacuation pump

Check with vacuum pump supplier to verify equipment is compatible for HFC134a. Robinair,

Model 15600 2 s t a g e , 6 c u b i c f e e t p e r m i n u t e p u m p i s recommended.

•

Four-way manifold gauge set, with low loss hoses

•

Leak detector

•

Charging cylinder

•

Line piercing saddle valve

(Schroeder valves). Seals must be HFC134a and ester oil compatible. Line piercing valves may be

used for diagnosis but are not suitable for evacuation or charging, due to minute holes pierced in

tubing. Do not leave mechanical access valves on system. Valves eventually will leak.

Molecules of HFC134a are smaller than other refrigerants and will leak where other refrigerants

would not.

•

Swagging tools

•

Flaring tools

•

Tubing cutter

•

Flux

•

Sil-Fos

•

Silver solder

•

Oil for swagging and flaring

•

Copper tubing

•

Dry nitrogen

99.5% minimum purity, with –40

O

F or lower dew point

•

Crimp tool

•

Tube bender

•

Micron vacuum gauge

•

Process tube adaptor kit

•

Heat trap paste

•

ICI appliance grade HFC134a

13.2 Drier

Replacement

Before opening refrigeration system, recover H FC 134a refrigerant for safe disposal.

Every time sealed HFC134a system is repaired, drier filter must be replaced.

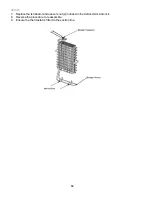

Cut drier out of system by completing the following steps. Do not unbraze drier filter. Applying heat to

remove drier will drive moisture into system.

WARNING

To avoid death or severe personal injury, cut drier at correct location. Cutting drier at incorrect

location will allow desiccant beads to scatter. If spilled, completely clear area of beads.

1. Score capillary tube close to drier and break.

2. Reform inlet tube to drier allowing enough space for large tube cutter.

3. Cut circumference of drier at 32mm below condenser inlet tube joint to drier.

Summary of Contents for RX256DT4X1

Page 11: ...321023 11 2 3 Refrigerant Flow...

Page 12: ...321023 12 2 4 Cabinet Air Flow...

Page 13: ...321023 13 2 5 Ice And Water Dispenser Diagram...

Page 14: ...321023 14 2 6 Water Valve Diagram...

Page 15: ...321023 15 2 7 Typical External Sweat Pattern...

Page 16: ...321023 16 3 INSTALLATION...

Page 17: ...321023 17...

Page 18: ...321023 18...

Page 76: ...321023 76 Ice Water Dispensing Board...

Page 78: ...321023 78 Mid Electronic Specification Control RX256DT4X1 RX256ET2B1 RX256ET2W1...

Page 104: ...321023 104 14 WIRING DIAGRAMS 14 1 Wiring Schematic RX256DT7X1...

Page 105: ...321023 105 14 2 Wiring Diagram RX256DT7X1...

Page 106: ...321023 106 14 3 Wiring Schematic RX256DT4X1 RX256ET2B1 RX256ET2W1...

Page 107: ...321023 107 14 4 Wiring Diagram RX256DT4X1 RX256ET2B1 RX256ET2W1...

Page 108: ...321023 108 NOTES...