Drive modules

188

3.

DRIVE MODULES

Mo

dula

r d

riv

es

128

DDS

HARDWARE

Ref.1310

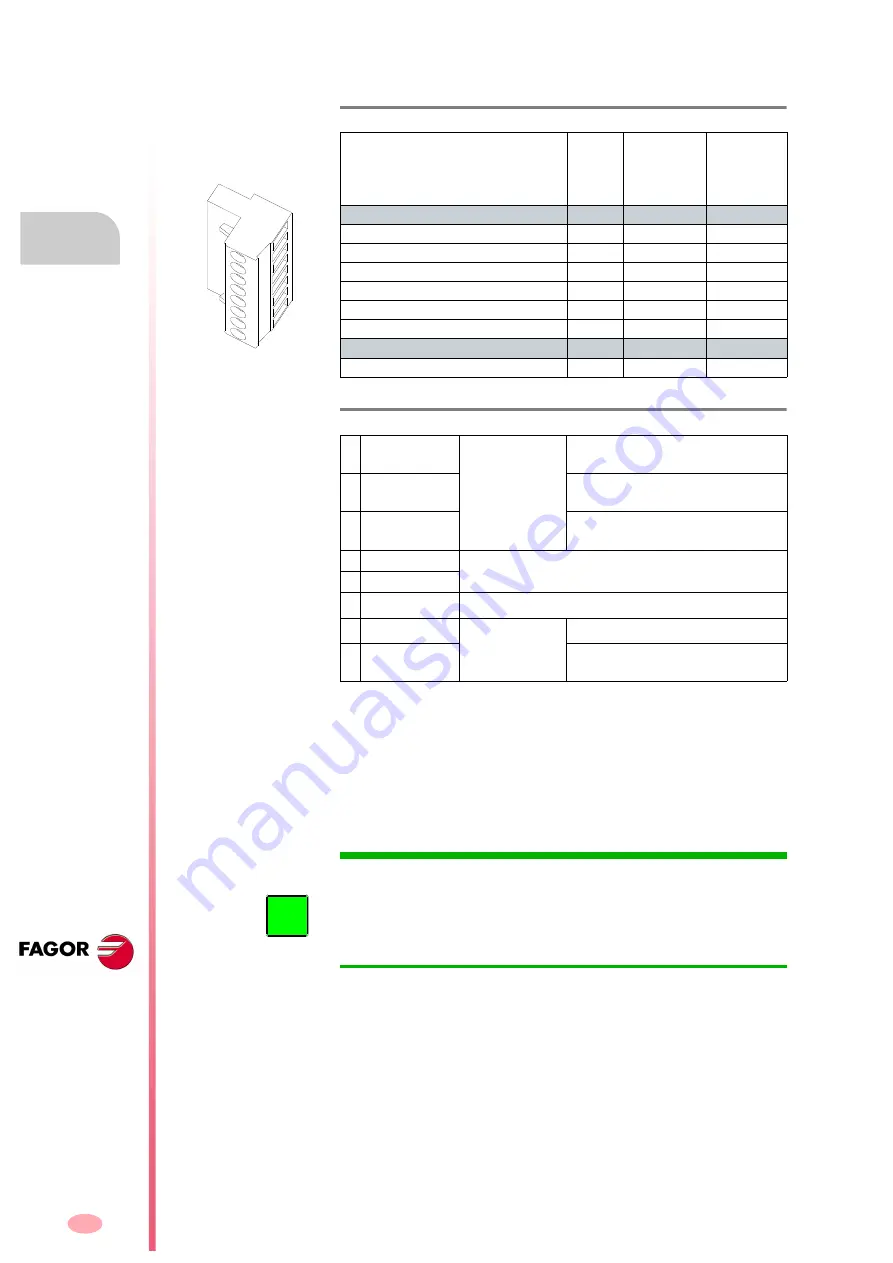

The following table shows the values for gap, tightening torque, sections

and other data of the plug-in connector for X2.

The description of the pins of this connector is:

SPEED ENABLE AND DRIVE ENABLE

Normal operating mode

1.

Activate the Drive Enable and Speed Enable inputs (24 V DC) in the

desired order. Before activating, the Soft Start process ( smoothly

reaching the power bus voltage ) must be over. The motor will have

torque only when Drive Enable is active and there is voltage at the

power bus. The motor speed will be controlled with a command when

the Speed Enable function is active.

2.

The motor will respond to all analog command variations only while

both inputs (Drive Enable and Speed Enable) are at 24 V DC. If any

of them is deactivated, the following will happen. See the operation

modes in figure

Deactivation of the Drive Enable input

The Drive Enable input lets the current circulate through the motor stator

windings. When it is powered with 24 V DC the current is enabled and the

drive can work.

If the Drive Enable input drops to 0 V DC (no voltage), the power circuit is

off and the motor will have not torque, hence not being governed and will

turn freely until it stops by friction.

T. H3/7

Characteristics of the pins of connector X2.

AXD/SPD/MMC

1.08

1.15

1.25

1.35

2.50

2.75

2.85

3.100

3.150

3.200

3.250

Connector data

Nr of poles

8

8

8

Gap (mm)

5

5

5

Min/max tightening torque (Nm)

0.5/0.6

0.5/0.6

0.5/0.6

Screw thread

M3

M3

M3

Min./max. section (mm²)

0.2/2.5

0.2/2.5

0.2/2.5

Rated current In (A)

12

12

12

Wire data

Length to strip (mm)

7

7

7

T. H3/8

Signals at the pins of connector X2 of the modular drive.

1

GND

Control signals

Reference 0 V for control signals

2

Drive Enable

Motor current enable

(24 V DC)

3

Speed Enable

Drive speed enable

(24 V DC)

4

Drive OK

Contact indicating module status (it opens in case of

failure). Limit 1 A at 24 V DC.

5

Drive OK

6

Chassis

Chassis connection.

7

0 V DC (IN)

Supply input for

the control

circuit

Reference 0 V

8

+24 V DC (IN)

Positive voltage input

(21

28 V DC)

x1

INFORMATION.

Activating the Drive Enable function requires to be re-

quested by the system in three different ways. They are: Electrical signal

at connector X2, variable BV7 (F00203), and variable DRENA of the PLC

when using the SERCOS or CAN interface. It could be deactivated

through any of them. Only via connector X2 is certified. See chapter

i

Summary of Contents for DDS

Page 1: ...DRIVE DDS Hardware manual Ref 1310...

Page 6: ...I 6 DDS HARDWARE Ref 1310...

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 16: ...16 Ref 1310 DDS HARDWARE...

Page 30: ...1 DESCRIPTION 30 Description DDS HARDWARE Ref 1310...

Page 94: ...2 POWER SUPPLIES 94 Power supplies DDS HARDWARE Ref 1310...

Page 188: ...3 DRIVE MODULES 188 Drive modules DDS HARDWARE Ref 1310...

Page 204: ...4 AUXILIARY MODULES 204 Auxiliary modules DDS HARDWARE Ref 1310...

Page 232: ...SELECTING CRITERIA 5 232 Selection criteria DDS HARDWARE Ref 1310...

Page 266: ...7 CABLES 266 Cables DDS HARDWARE Ref 1310...

Page 312: ...8 INSTALLATION 312 Installation DDS HARDWARE Ref 1310...

Page 326: ...9 FUNCTIONAL SAFETY 326 Functional safety DDS HARDWARE Ref 1310...

Page 354: ...10 CONNECTION DIAGRAMS 354 Connection diagrams DDS HARDWARE Ref 1310...

Page 378: ...12 SALES REFERENCES 378 Sales references DDS HARDWARE Ref 1310...

Page 384: ...13 COMPATIBILITY 384 Compatibility DDS HARDWARE Ref 1310...

Page 385: ......