Connection diagrams

CON

N

ECTION DIAGRAMS

Diagr

a

ms

with a XPS

power supply

10.

343

DDS

HARDWARE

Ref.1310

F. H10/16

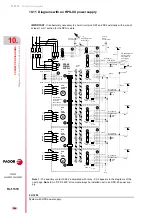

System with a XPS power supply. Diagram of the maneuver.

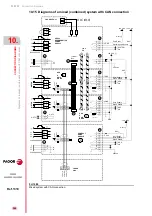

F. H10/17

General diagram of a DDS system with a XPS power supply.

+24VDC

EMERGENCY

X+

X-

Y+

Y-

Z+

Z-

EMERG.

STOP

XPS

SYSTEM OK

I1 PLC

CNC EMERG.

O1 PLC

EMERGENCY LINE GND

Delay off

-KA3

DRIVE

ENABLES

(See GP9)

SYSTEM

SPEED

ENABLE

-KA2

-KM1

ON

OFF

KA2

KA1

KA3

KA2

KA2

ON

Green

OFF

Red

ON

OFF

to SPEED ENABLES

-KA7

-KA4

-KA5

-KA6

BRAKE

CONTROL

BRK

(See GP9)

CNC

ENABLE

X

CNC

ENABLE

S

CNC

ENABLE

Y

CNC

ENABLE

Z

KA2

KA1

-KA1

t seconds

Note.

CNC EMERG. will always be assigned to I1/O1 of the PLC with an 8055/55i CNC. With an 8070

CNC, it may be assigned to any I/O of the PLC. The contacts associated with relays - KA2, - KA3, - KA4,

- KA5, - KA6 and - KA7 are shown inside a circle in figure

and the contactor - KM1 in figure

.

Note.

The relay - KA3 uses delayed deac-

tivation for contactor - KM1 (t seconds) in

order to be able to keep it closed long

enough to return to mains the excess

energy generated while braking the motor.

Make sure that the delay t programmed at

relay - KA3 is slightly longer than the brak-

ing time until the motor comes to full stop.

See also parameter GP9 in the

“man_dds_soft.pdf” manual.

OPERATION DIAGRAM. XPS-XX

PE

- S1

MECHANICAL

MAIN SWITCH

- F3

- F4

- F5

MAINS FILTER xxA

L1

L3

L2

L1

3x400-460 VAC

2x400-460 VAC

R

S

T

R

S

T

CONTACTOR

- KM1

L2

N

- Q1

DIFFERENTIAL

BREAKER

WARNING.

When using an isolating transformer, the secondary must be

connected in star and its middle point must be connected to GND.

POWER M

AINS

IT A MUST TO USE FUSES

TO THE POWER CONNECTOR

XPS-XX POWER SUPPLY

TO THE X3 CONNECTOR

XPS-XX POWER SUPPLY

Note.

Observe that having the main key - S1 closed, although the

power contactor - KM1 is open, the internal auxiliary power supply

of the XPS remains connected through its connector X3 to feed the

control circuits of the drive.

GENERAL DIAGRAM. XPS-XX

Summary of Contents for DDS

Page 1: ...DRIVE DDS Hardware manual Ref 1310...

Page 6: ...I 6 DDS HARDWARE Ref 1310...

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 16: ...16 Ref 1310 DDS HARDWARE...

Page 30: ...1 DESCRIPTION 30 Description DDS HARDWARE Ref 1310...

Page 94: ...2 POWER SUPPLIES 94 Power supplies DDS HARDWARE Ref 1310...

Page 188: ...3 DRIVE MODULES 188 Drive modules DDS HARDWARE Ref 1310...

Page 204: ...4 AUXILIARY MODULES 204 Auxiliary modules DDS HARDWARE Ref 1310...

Page 232: ...SELECTING CRITERIA 5 232 Selection criteria DDS HARDWARE Ref 1310...

Page 266: ...7 CABLES 266 Cables DDS HARDWARE Ref 1310...

Page 312: ...8 INSTALLATION 312 Installation DDS HARDWARE Ref 1310...

Page 326: ...9 FUNCTIONAL SAFETY 326 Functional safety DDS HARDWARE Ref 1310...

Page 354: ...10 CONNECTION DIAGRAMS 354 Connection diagrams DDS HARDWARE Ref 1310...

Page 378: ...12 SALES REFERENCES 378 Sales references DDS HARDWARE Ref 1310...

Page 384: ...13 COMPATIBILITY 384 Compatibility DDS HARDWARE Ref 1310...

Page 385: ......