Epson DFX-9000

Revision B

Operating Principles

Circuit operation

83

SP Motor drive circuit

The SP motor is a DC brushless motor. A dedicated brushless motor

control IC is used to control the speed and position. The position of the

SP motor is controlled using encoder pulse

counts, and the speed is

controlled using Proportional, Integral, Derivative (PID)

and closed-

loop control. The following shows a detailed block diagram and timing

chart of the SP motor drive circuit.

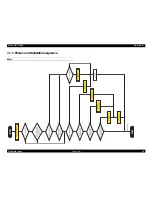

Figure 2-27. SP motor drive circuit block diagram

SP motor control signal definitions

CR_C[1:3] is a Hall-effect sensor input signal. When the motor is in

an IN+ > IN- state, the signal is high, and the reverse state is low.

M_CWCCW is a normal/reverse rotation input signal that

determines the direction of the Carrier unit.

M_STSP is a start/stop control signal. When the signal is low, the

motor starts driving. When the signal is high, the motor stops

driving.

M_BRAKE is a brake input signal. When the signal is low, the

motor is braked. When the signal is high, the motor rotates normally.

PWMIN is a pulse input signal (M_TIM1), and its output is

controlled based on the duty levels. When the signal input is low, the

pulse output turns “ON”. When the input is high, the pulse output

turns “OFF”.

UH, UV, UW are PWM output signals that are controlled based on

the duty levels. UH, UV, UW are normally controlled in a saturated

state.

RF is an output current detection terminal. The output current is

determined according to the detected resistance (Iout=0.5/Rf).

PWM frequency is determined according to the capacity of an

external capacitor. It is set to approximately 20 kHz. The frequency

can be determined by calculation using Fpwm=1/(45000*C).

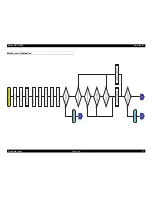

Figure 2-28. Timing Chart

ASIC

Power Unit

M_CWCCW

M_STSP

M_BRAKE

PWMIN

UL

UH

VL

VH

WL

WH

SP MOTOR

Current detection

section

+42V

CR_C[1:3]

(RF)

M_TIM1

SP Motor

Driver

INLK SW ASY

Fuse

(125 V, 8 A)

MOSFET

(U phase)

MOSFET

(V phase)

MOSFET

(W phase)

IN1

IN2

IN3

UH

VH

WH

UL

VL

WL

indicates PWM output.

Summary of Contents for DFX-9000

Page 1: ...EPSONDFX 9000 Serial Impact Dot Matrix Printer SEDM04003 SERVICE MANUAL ...

Page 8: ...C H A P T E R 1 PRODUCT DESCRIPTION ...

Page 61: ...Epson DFX 9000 Revision B Product Description Dimensions and weight 54 ...

Page 62: ...C H A P T E R 2 OPERATING PRINCIPLES ...

Page 99: ...Epson DFX 9000 Revision B Operating Principles Circuit operation 92 ...

Page 100: ...C H A P T E R 3 TROUBLESHOOTING ...

Page 104: ...Epson DFX 9000 Revision B Troubleshooting Overview 97 Mechanism initialization e e e e e ...

Page 107: ...Epson DFX 9000 Revision B Troubleshooting Overview 100 PAPER FEEDING FF APG APPROACH ...

Page 130: ...C H A P T E R 4 DISASSEMBLY AND ASSEMBLY ...

Page 218: ...C H A P T E R 5 ADJUSTMENT ...

Page 263: ...Epson DFX 9000 Revision B Adjustment Additional functions 256 ...

Page 264: ...C H A P T E R 6 MAINTENANCE ...

Page 286: ...C H A P T E R 7 APPENDIX ...

Page 297: ......

Page 298: ......

Page 299: ......

Page 300: ......

Page 301: ......

Page 302: ......

Page 303: ......

Page 304: ......

Page 305: ......

Page 306: ......

Page 307: ......

Page 308: ......

Page 309: ......

Page 310: ......

Page 311: ......

Page 312: ......

Page 313: ......

Page 314: ......

Page 315: ......

Page 316: ......

Page 317: ......

Page 318: ......

Page 319: ......

Page 320: ......

Page 321: ......

Page 322: ......

Page 323: ......

Page 324: ...EPSON DFX 9000 Revision B Appendix Component Layout 317 7 4 Component Layout ...

Page 333: ...EPSON DFX 9000 Revision B Appendix Parts list 326 ...