Epson DFX-9000

Revision B

Maintenance

Overview

258

6.1 Overview

6.1.1 Preventive maintenance

Preventive maintenance is important to keep the printer in the best

working condition and to help prevent premature failure.

Keep the printer as clean as possible. If necessary, use denatured alcohol

to clean the exterior case. Use a vacuum cleaner to remove any dust and

paper debris accumulated in the printer.

6.2 Lubrication

6.2.1 Lubricants

The use of appropriate lubricants is critical to printer performance,

especially in low temperatures. Epson has extensively tested and

analyzed various types of oil and grease, and specifies the lubricants in

the table below.

W A R N I N G

Before disassembling, assembling or adjusting the

printer, disconnect the power supply cable from the AC

power socket, and wait at least 5 minutes for capacitors

to drain. Failure to do so might cause personal injury.

Be careful with the Printhead when you handle it. It

may be very hot immediately after printing.

Do not touch the heat sink attached to the switching

FETs (Q101, 102, 103, 301, 302, 303) on the power

supply board immediately after power off. It may be

very hot.

C A U T I O N

Do not use paint thinner, trichloroethylene, or ketone-

based solvents on the plastic components of the printer.

Never use oil or grease other than those specified in this

manual; use of other lubricants can damage the printer

or its components.

When using compressed air products; such as air duster,

for cleaning during repair and maintenance, the use of

such products containing flammable gas is prohibited.

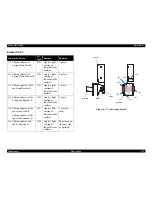

Table 6-1. Lubrication

Type

Name

Supplier

Part No.

Oil

O-31

Epson

1080618

G-41

Epson

1017323

Grease

O-6

Epson

T.B.D.

(FLOIL T-7)

Epson

T.B.D.

C A U T I O N

Lubricants must be applied during the reassembly process.

Summary of Contents for DFX-9000

Page 1: ...EPSONDFX 9000 Serial Impact Dot Matrix Printer SEDM04003 SERVICE MANUAL ...

Page 8: ...C H A P T E R 1 PRODUCT DESCRIPTION ...

Page 61: ...Epson DFX 9000 Revision B Product Description Dimensions and weight 54 ...

Page 62: ...C H A P T E R 2 OPERATING PRINCIPLES ...

Page 99: ...Epson DFX 9000 Revision B Operating Principles Circuit operation 92 ...

Page 100: ...C H A P T E R 3 TROUBLESHOOTING ...

Page 104: ...Epson DFX 9000 Revision B Troubleshooting Overview 97 Mechanism initialization e e e e e ...

Page 107: ...Epson DFX 9000 Revision B Troubleshooting Overview 100 PAPER FEEDING FF APG APPROACH ...

Page 130: ...C H A P T E R 4 DISASSEMBLY AND ASSEMBLY ...

Page 218: ...C H A P T E R 5 ADJUSTMENT ...

Page 263: ...Epson DFX 9000 Revision B Adjustment Additional functions 256 ...

Page 264: ...C H A P T E R 6 MAINTENANCE ...

Page 286: ...C H A P T E R 7 APPENDIX ...

Page 297: ......

Page 298: ......

Page 299: ......

Page 300: ......

Page 301: ......

Page 302: ......

Page 303: ......

Page 304: ......

Page 305: ......

Page 306: ......

Page 307: ......

Page 308: ......

Page 309: ......

Page 310: ......

Page 311: ......

Page 312: ......

Page 313: ......

Page 314: ......

Page 315: ......

Page 316: ......

Page 317: ......

Page 318: ......

Page 319: ......

Page 320: ......

Page 321: ......

Page 322: ......

Page 323: ......

Page 324: ...EPSON DFX 9000 Revision B Appendix Component Layout 317 7 4 Component Layout ...

Page 333: ...EPSON DFX 9000 Revision B Appendix Parts list 326 ...