U n i v e r s a l l y

A d j u s t a b l e V D T

S t a n d

Tools Required

- 4mm Allen wrench (provided)

-5mm Allen wrench (provided)

-6mm Allen Wrench (provided)

-Phillips head screwdriver

1. Attach the

Feet

to the adjustable

Base Frame

using

the M8 x 1.00”(25mm) Socket head screws and lock

washers. Tighten securely using the 6mm wrench.

Install the round

and square

End Caps

on the

Feet. See

Figure 1

.

NOTE

: Install the Feet with the longer portion to

the rear of the unit.

2. Assemble the left and right hand

Top Supports

to

the Base Frame using the M8 x .64”(16mm) Socket

flat head cap screws. Tighten securely using the

5mm wrench. See

Figure 1

.

3. Place the

Rear Surface

(keyboard and monitor lam-

inate tops are packaged separately) onto the rear

Top Supports. Align the holes in one of the

Surface

Mount

with the holes in the bottom of the Rear Sur-

face. Note that the Top Supports are sandwiched be-

tween the Rear Surface and the Surface Mounts.

Attach the Surface Mounts to the Rear Surface using

the #8 x 1.25”(30mm) screws provided. Repeat this

procedure for the

Front Surface

. See

Figure 2

.

NOTE

: The radiused side of both Surfaces face to-

wards the front of the unit.

4. The

Front Crank Assembly

may be installed on the

left or right side of the unit. Fasten the

Mounting

Block

to the appropriate Top Support using the two

M-5 x .38”(10mm) Socket head screws provided.

Tighten securely using the 4mm wrench. See

Figure

2

.

Insert the Front Crank Assembly through the Mount-

ing Block and onto the

Drive Pin

located on the

Base Frame. Fasten the Crank Assembly to the Drive

Pin with the

Connector Clip

. See

Figure 2

.

5. Install the removable

Rear Crank

into the Rear Sur-

face drive mechanism on either side of the Surface.

The holes in the Surface must be aligned with the

drive mechanism on the Base Frame. See

Figure 2

.

Universally Adjustable VDT Stand

Figure 1

Foot

Square end

cap

Round end

cap

Adjustable base

frame

M-8 x 1.00”(25mm)

Socket head cap

screws

Washers

M-8 x .64”(16mm)

Socket flat head

screws

Top support

Rear crank

Front surface

Rear surface

Surface mount

Front crank

assembly

Mounting block

M-5 x .38 (10mm)

Socket head screws

Connector

clip

#8 x 1.25” (30mm)

screws

Figure 2

82743

technical furniture

B-1

Summary of Contents for LINX

Page 1: ...Modular Furniture LINX Modular Furniture Installation manual...

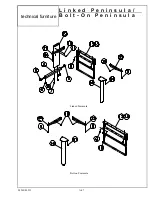

Page 24: ...84913 Bolt on Peninsula P e n i n s u l a B o l t o n technical furniture...

Page 41: ...R e t r o f i t K i t N o v a c o n t 86270 technical furniture A 34...

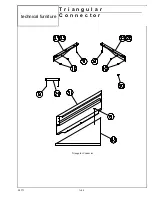

Page 51: ...84571 Triangular Connector T r i a n g u l a r C o n n e c t o r technical furniture A 44...

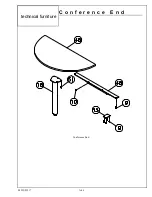

Page 53: ...84252 85217 Conference End C o n f e r e n c e E n d technical furniture A 46...

Page 56: ...81071 B C o n f e r e n c e T a b l e technical furniture A 49...

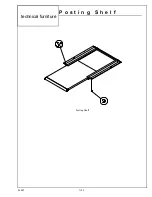

Page 57: ...84085 Posting Shelf P o s t i n g S h e l f technical furniture A 50...

Page 58: ...81046 Storage Shelf S t o r a g e S h e l f technical furniture A 51...

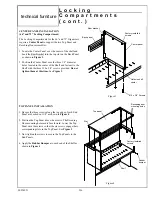

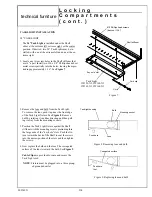

Page 78: ...80954LX L o c k i n g C o m p a r t m e n t s c o n t technical furniture D 11...

Page 112: ...85089 W h i t e P e g A n d B i n B o a r d s c o n t technical furniture E 12...

Page 119: ...85082 F a b r i c T e c h W a l l c o n t technical furniture E 19...

Page 122: ...85093 C o r n e r L a m i n a t e H o o k O n S h e l v e s c o n t technical furniture E 22...