SD-410-QS (H) (06/15)

Page 24

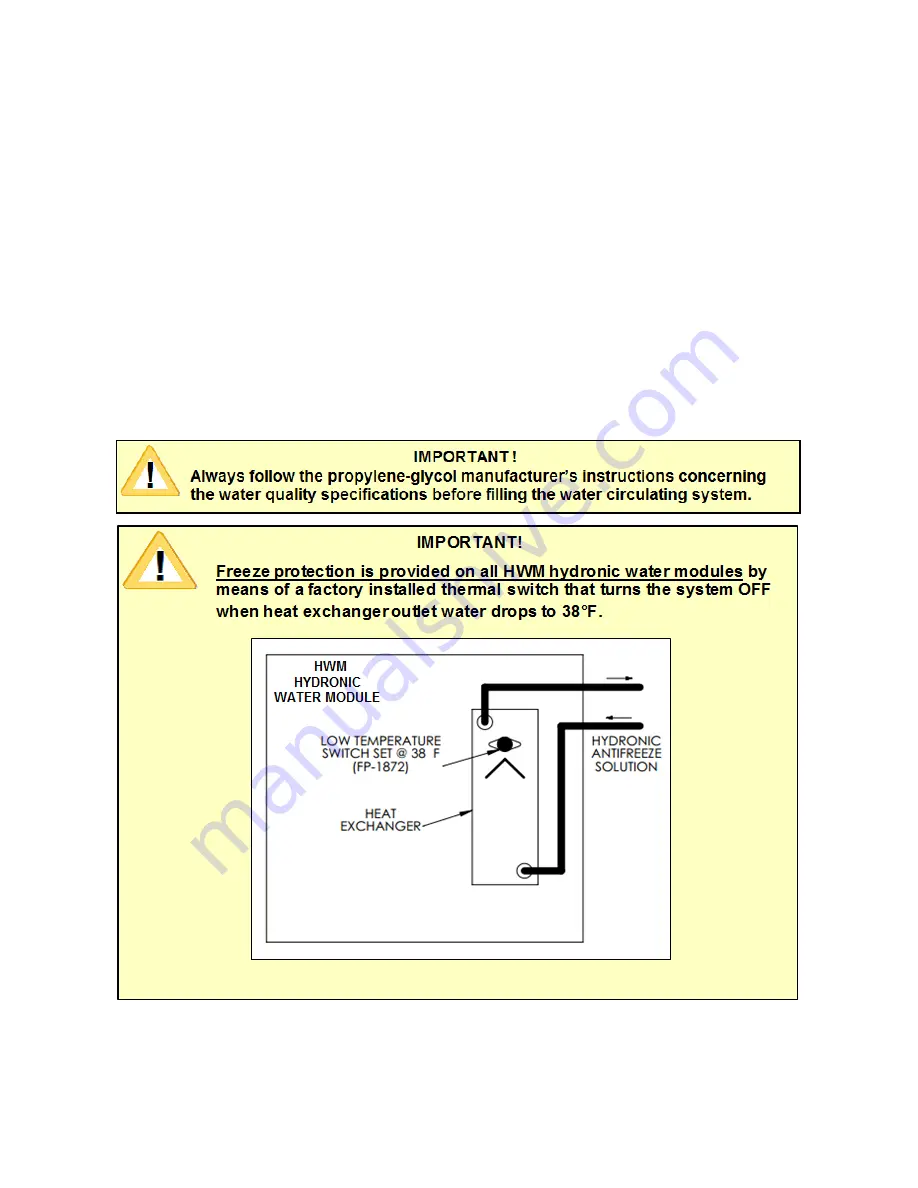

General guidelines for introducing propylene glycol into the water circulating system follow. The

manufacturer’s specific instructions and industry standards always take precedence when introducing

propylene-glycol to the system.

Calculate the quantity of inhibited propylene-glycol (fluid) required to achieve the

desired results.

Introduce a sufficient quantity of water to the system and pressure check to ensure a

sealed system.

Drain some water from the system to provide enough volume for the calculated

amount of fluid.

Add the correct amount of fluid and any water needed to completely refill the system,

allowing for liquid expansion due to operating temperature.

Circulate the inhibited propylene-glycol antifreeze solution for at least 24 hours to

ensure complete mixing. Check the liquid concentration to assure that the correct

mixture is obtained.

Summary of Contents for AVS-0030-A

Page 15: ...SD 410 QS H 06 15 Page 15 Figure 8a SD H Compressor Unit Electrical Ladder Diagram 230 1 60...

Page 16: ...SD 410 QS H 06 15 Page 16 Figure 8b SD H Compressor Unit Electrical Schematic Diagram 230 1 60...

Page 17: ...SD 410 QS H 06 15 Page 17 Figure 9a SD H Compressor Unit Electrical Ladder Diagram 230 3 60...

Page 18: ...SD 410 QS H 06 15 Page 18 Figure 9b SD H Compressor Unit Electrical Schematic Diagram 230 3 60...

Page 29: ...SD 410 QS H 06 15 Page 29 Figure 15 Disassembled Plug Connector...

Page 49: ...SD 410 QS H 06 15 Page 49 Figure 38 Cooling Mode Start Up...

Page 58: ...SD 410 QS H 06 15 Page 58...

Page 59: ...SD 410 QS H 06 15 Page 59...

Page 60: ...SD 410 QS H 06 15 Page 60...

Page 61: ...SD 410 QS H 06 15 Page 61...

Page 62: ...SD 410 QS H 06 15 Page 62...

Page 63: ...SD 410 QS H 06 15 Page 63...