OPERATOR’S MANUAL

Control Point

®

11001-1489-201702 Rev B

TROUBLESHOOTING / 93

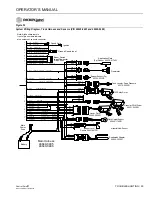

The RED wire should read battery voltage (+12V) and the BRN wire

should read a voltage equal to a percentage of +12V determined by PWM

SAT value entered under LIQUID CONFIGURATION (F5) (i.e. If PWM

SAT is 90, then a reading of +10.8V –12 x .9 = 10.8 should be present).

Check voltage readings at the pump or solenoid coil on the valve. The

RED wire supplies the PWM voltage signal to the pump or solenoid coil,

while the BLK wire is signal ground. Voltage reading should be equal to

those above.

2. If voltages are present but sprayer does not spray, the pump, solenoid

coil, hydraulic valve, or hydraulic flow may be faulty.If voltages are not

present, check wiring harnesses for cuts or shorts, then replace the

liquid valve driver. If this does not solve problem, replace the console.

Summary of Contents for Control Point

Page 1: ...CONTROL POINT CONTROL SYSTEM Operator s Manual SINCE 1966 ...

Page 5: ...OPERATOR S MANUAL Control Point 11001 1489 201702 Rev B IV ...

Page 7: ...OPERATOR S MANUAL Control Point 11001 1489 201702 Rev B 2 SAFETY NOTICES ...

Page 13: ...OPERATOR S MANUAL Control Point 11001 1489 201702 Rev B 8 INTRODUCTION ...

Page 29: ...OPERATOR S MANUAL Control Point 11001 1489 201702 Rev B 24 START UP AND FAMILIARIZATION ...

Page 77: ...OPERATOR S MANUAL Control Point 11001 1489 201702 Rev B 72 KEYBOARD PROGRAMMING ...

Page 79: ...OPERATOR S MANUAL Control Point 11001 1489 201702 Rev B 74 SYSTEM CALIBRATION ...

Page 91: ...OPERATOR S MANUAL Control Point 11001 1489 201702 Rev B 86 SYSTEM CALIBRATION ...