OPERATOR’S MANUAL

Control Point

®

11001-1489-201702 Rev B

92 / TROUBLESHOOTING

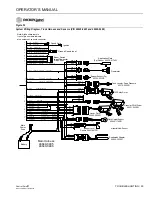

SYSTEM DOES NOT OPERATE

Probable Cause

If the system does not respond with the Master switch in Auto or Unload or

the Blast button has not effect, the hydraulic valve may not be opening to

supply hydraulic oil to the conveyor motor (spreader system) or the pump

may not be rotating to supply liquid to the spray bar (liquid system).

Corrective Action

The following four steps describe repair for a pulse width modulated

hydraulic valve (Rexroth, Gresen, Vickers, Parker, etc.). Begin by

disconnecting the electrical connections at the solenoid coil and then set

the MASTER Switch into UNLOAD position to prevent possible damage to

the PWM valve driver and coil.

1. Check voltage readings on the granular valve connector of the main

harness at pin 16 and 8. Use pin 15 as ground. Pin 16 should read

battery voltage (+12V); pin 8 reads a percentage of +12V determined

by PWM SAT value entered under Granular Configuration (F3). (i.e. If

PWM SAT is 40, then a reading of +4.8 V. –12 x .40 = 4.8 be present).

2. Check voltage readings at the solenoid valve coil. The WHT wire

supplies the PWM voltage signal to the coil; the GRY wire is signal

ground. Voltage reading should be equal to reading in step above. If

voltages are not present, check wiring harnesses for cuts or shorts.

3. If voltages are present a hydraulic valve or hydraulic flow problem is

indicated.

4. If the above checks are normal, replace the PWM valve driver. If this

does not the solve problem, replace the console.

Corrective Action for Granular Channel

Begin by disconnecting the electrical connections at the solenoid coil. Then

set the MASTER switch to the UNLOAD position for the following two steps

to prevent possible actuator damage.

1. Check voltage readings on the granular valve connector of the main

harness at pins 16 and 8. Use pin 15 as ground. Pin 16 and 8 should

read battery voltage (+12V).

2. If voltages are present and actuator does not rotate, replace the

actuator.

3. If voltages are not present replace main harness, valve extension

cable, or console.

Corrective Action for a Sprayer Channel

If the sprayer system is not spraying, begin by disconnecting the electrical

connections at the pump or solenoid coil. Then switch the MASTER switch

to the UNLOAD position for the following checks to prevent possible

damage to the liquid valve driver and coil.

1. Check voltage reading on the RED and BRN wires at the liquid valve

connector of the main harness. Use the BLK wire as ground.

Summary of Contents for Control Point

Page 1: ...CONTROL POINT CONTROL SYSTEM Operator s Manual SINCE 1966 ...

Page 5: ...OPERATOR S MANUAL Control Point 11001 1489 201702 Rev B IV ...

Page 7: ...OPERATOR S MANUAL Control Point 11001 1489 201702 Rev B 2 SAFETY NOTICES ...

Page 13: ...OPERATOR S MANUAL Control Point 11001 1489 201702 Rev B 8 INTRODUCTION ...

Page 29: ...OPERATOR S MANUAL Control Point 11001 1489 201702 Rev B 24 START UP AND FAMILIARIZATION ...

Page 77: ...OPERATOR S MANUAL Control Point 11001 1489 201702 Rev B 72 KEYBOARD PROGRAMMING ...

Page 79: ...OPERATOR S MANUAL Control Point 11001 1489 201702 Rev B 74 SYSTEM CALIBRATION ...

Page 91: ...OPERATOR S MANUAL Control Point 11001 1489 201702 Rev B 86 SYSTEM CALIBRATION ...