Danfoss offers brake resistors with duty cycle of 5%, 10%

and 40%. If a 10% duty cycle is applied, the brake resistors

are able to absorb brake power for 10% of the cycle time.

The remaining 90% of the cycle time will be used on

dissipating excess heat.

Make sure the resistor is designed to handle the required

braking time.

The max. permissible load on the brake resistor is stated as

a peak power at a given intermittent duty cycle and can

be calculated as:

The brake resistance is calculated as shown:

Rbr Ω =

Udc

2

Ppeak

where

P

peak

= P

motor

x M

br

[%] x η

motor

x η

VLT

[W]

As can be seen, the brake resistance depends on the

intermediate circuit voltage (U

dc

).

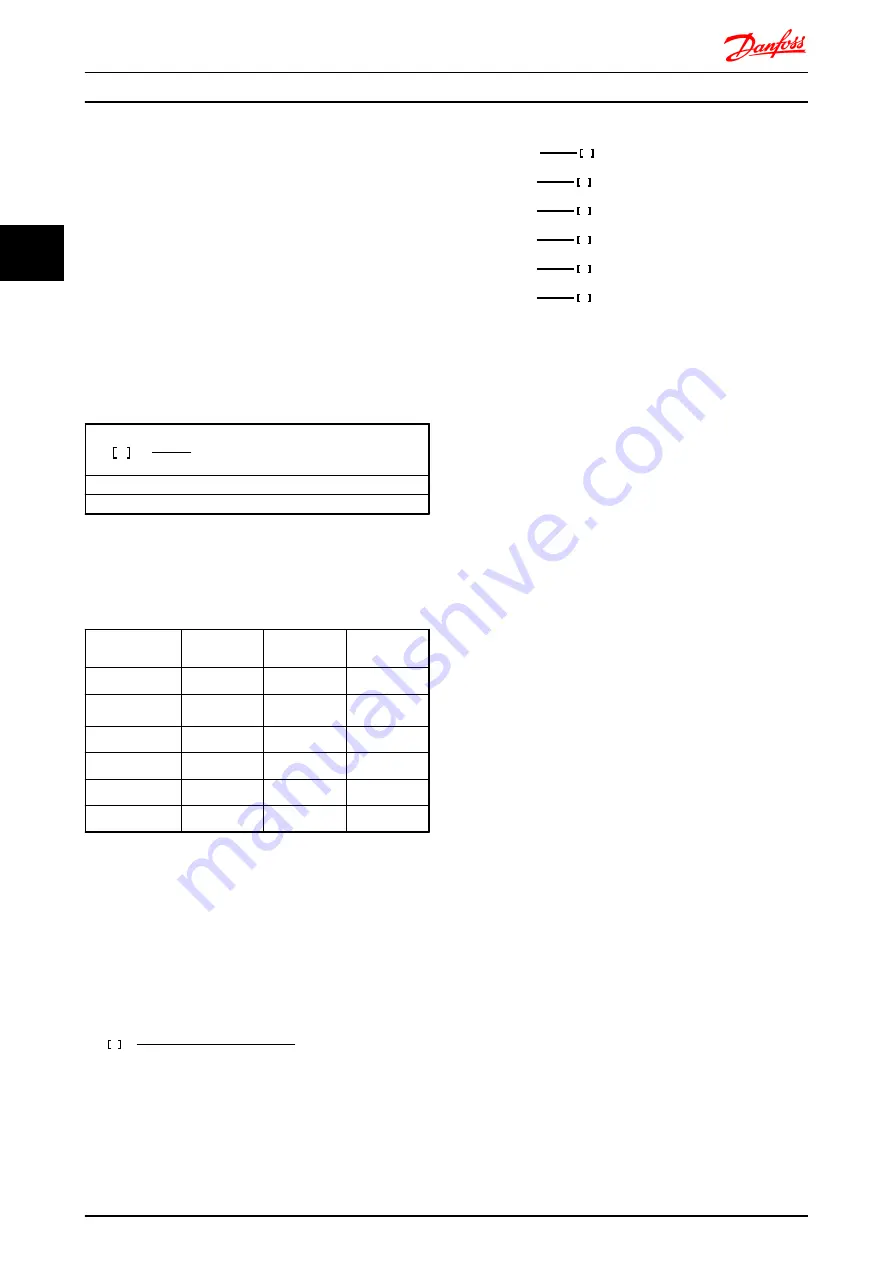

The FC 301 and FC 302 brake function is settled in 4 areas

of mains.

Size

Brake active Warning

before cut

out

Cut out (trip)

FC301/302 3 x

200-240 V

390V (UDC)

405V

410V

FC301 3 x 380-480

V

778V

810V

820V

FC302 3 x 380-500

V*

810V/ 795V

840V/ 828V

850V/ 855V

FC302 3 x 525-600

V

943V

965V

975V

FC302 3 x 525-690

V

1084V

1109V

1130V

* Power size

dependent

Check that the brake resistor can cope with a voltage of

410V, 820V, 850V, 975V or 1130V - unless Danfoss brake

resistors are used.

Danfoss recommends the brake resistance R

rec

, i.e. one that

guarantees that the frequency converter is able to brake at

the highest braking torque (M

br(%)

) of 160%. The formula

can be written as:

Rrec Ω =

Udc

2 x 100

Pmotor x Mbr (%) xηVLT x ηmotor

η

motor

is typically at 0.90

η

VLT

is typically at 0.98

For 200V, 480V, 500V and 600V frequency converters, R

rec

at 160% braking torque is written as:

200

V : Rrec =

107780

Pmotor

Ω

480

V : Rrec =

375300

Pmotor

Ω 1)

480

V : Rrec =

428914

Pmotor

Ω 2)

500

V : Rrec =

464923

Pmotor

Ω

600

V : Rrec =

630137

Pmotor

Ω

690

V : Rrec =

832664

Pmotor

Ω

1) For frequency converters ≤ 7.5 kW shaft output

2) For frequency converters 11 - 75 kW shaft output

NOTE

The resistor brake circuit resistance selected should not be

higher than that recommended by Danfoss. If a brake

resistor with a higher ohmic value is selected, the 160%

braking torque may not be achieved because there is a risk

that the frequency converter cuts out for safety reasons.

NOTE

If a short circuit in the brake transistor occurs, power

dissipation in the brake resistor is only prevented by using

a mains switch or contactor to disconnect the mains for

the frequency converter. (The contactor can be controlled

by the frequency converter).

NOTE

Do not touch the brake resistor as it can get very hot

while/after braking. The brake resistor must be placed in a

secure environment to avoid fire risk

D-F size frequency converters contain more than one brake

chopper. Consequently, use one brake resistor per brake

chopper for those frame sizes.

3.8.4 Control with Brake Function

The brake is protected against short-circuiting of the brake

resistor, and the brake transistor is monitored to ensure

that short-circuiting of the transistor is detected. A relay/

digital output can be used for protecting the brake resistor

against overloading in connection with a fault in the

frequency converter.

In addition, the brake makes it possible to read out the

momentary power and the mean power for the latest 120

seconds. The brake can also monitor the power energizing

and make sure it does not exceed a limit selected in

2-12 Brake Power Limit (kW)

. In

2-13 Brake Power Monitoring

,

select the function to carry out when the power

transmitted to the brake resistor exceeds the limit set in

2-12 Brake Power Limit (kW)

.

Introduction to FC 300

FC 300 Design Guide

44

MG.33.BD.02 - VLT

®

is a registered Danfoss trademark

3

3