Field Setting

Si39-502A

112

Test Operation

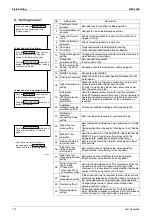

No.

Setting item

Description

1

Cool/heat unified

address

Sets address for cool/heat unified operation.

2

Low noise/demand

address

Address for low noise/demand operation

5

Indoor unit forced

fan H

Allows forced operation of indoor unit fan while unit is

stopped. (H tap)

6

Indoor unit forced

operation

Allows forced operation of indoor unit.

8

Te setting

Target evaporation temperature for cooling

9

Tc setting

Target condensation temperature for heating

10

Defrost changeover

setting

Changes the temperature condition for defrost and sets to

quick defrost or slow defrost.

11

Sequential

operation setting

Sets sequential operation

(Factory set to ON)

12

External low noise

setting / Demand

setting

Reception of external low noise or demand signal

13

AIRNET address

Set address for AIRNET.

16

Setting of hot water

Make this setting to conduct heating operation with hot

water heater.

18

High static pressure

setting

Make this setting in the case of operating in high static

pressure mode with diffuser duct mounted.

(In order to mount the diffuser duct, remove the cover

from the outdoor unit fan.)

19

Emergency

operation

(STD compressor

operation

prohibited)

Used to operate system only with inverter compressor

when STD compressor malfunctions. This is a temporary

operation extremely impairing comfortable environment.

Therefore, prompt replacement of the compressor is

required.

20

Additional

refrigerant charge

operation setting

Carries out additional refrigerant charge operation.

21

Refrigerant

recovery /

vacuuming mode

setting

Sets to refrigerant recovery or vacuuming mode.

22

Night-time low

noise setting

Sets automatic nighttime low noise operation in a simple

way.

The operating time is based on “Starting set” and “Ending

set”.

24

ENECUT test

operation

Used to forcedly turn ON the ENECUT. (Be noted that the

ENECUT is only functional with outdoor unit in the

stopped state - Japanese domestic model only.)

25

Setting of external

low noise level

Sets low noise level when the low noise signal is input

from outside.

26

Night-time low

noise operation

start setting

Sets starting time of nighttime low noise operation.

(Night-time low noise setting is also required.)

27

Night-time low

noise operation end

setting

Sets ending time of nighttime low noise operation.

(Night-time low noise setting is also required.)

28

Power transistor

check mode

∗

Check after

disconnection of

compressor wires

Used for trouble diagnosis of DC compressor. Since the

waveform of inverter is output without wiring to the

compressor, it is convenient to probe whether the trouble

comes from the compressor or PC board.

29

Capacity

precedence setting

If the capacity control is required, the low noise control is

automatically released by this setting during carrying out

low noise operation and nighttime low noise operation.

30

Demand setting 1

Changes target value of power consumption when

demand control 1 is input.

32

Normal demand

setting

Normally enables demand control 1 without external

input. (Effective to prevent a problem that circuit breaker

of small capacity is shut down due to large load.

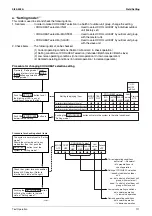

b. “Setting mode 2”

<Selection of setting items>

<Selection of setting conditions>

Push and hold the MODE (BS1)

button for 5 seconds and set to

“Setting mode 2”.

Push the SET (BS2) button and set

the LED display to a setting item

shown in the table on the right.

↓

Push the RETURN (BS3) button and

decide the item. (The present setting

condition is blinked.)

Push the SET (BS2) button and set

to the setting condition you want.

↓

Push the RETURN (BS3) button and

decide the condition.

Push the RETURN (BS3) button and

set to the initial status of “Setting

mode 2”.

∗

If you become unsure of how to

proceed, push the MODE (BS1)

button and return to setting mode 1.

(V2764)

Summary of Contents for VRV II RXYQ8MY1K

Page 53: ...Specifications Si39 502A 42 Specifications...

Page 143: ...Field Setting Si39 502A 132 Test Operation...

Page 258: ...Si39 502A Wiring Diagrams for Reference Appendix 247 FXCQ40M 50M 80M 125MVE 3D039557A...

Page 260: ...Si39 502A Wiring Diagrams for Reference Appendix 249 FXKQ25M 32M 40M 63MVE 3D039564A...

Page 264: ...Si39 502A Wiring Diagrams for Reference Appendix 253 FXMQ40M 50M 63M 80M 100M 125MVE 3D039620A...

Page 265: ...Wiring Diagrams for Reference Si39 502A 254 Appendix FXMQ200M 250MVE 3D039621A...

Page 266: ...Si39 502A Wiring Diagrams for Reference Appendix 255 FXHQ32M 63M 100MVE 3D039801C...

Page 267: ...Wiring Diagrams for Reference Si39 502A 256 Appendix FXAQ20M 25M 32M 40M 50M 63MVE 3D034206A...

Page 269: ...Wiring Diagrams for Reference Si39 502A 258 Appendix FXUQ71M 100M 125MV1 3D044973...

Page 270: ...Si39 502A Wiring Diagrams for Reference Appendix 259 FXAQ20MH 25MH 32MH 40MH 50MHV1 3D046348A...

Page 271: ...Wiring Diagrams for Reference Si39 502A 260 Appendix FXLQ20MH 25MH 32MH 40MH 50MHV1 3D046787A...

Page 272: ...Si39 502A Wiring Diagrams for Reference Appendix 261 BEVQ50MVE 3D046579A Notes...

Page 273: ...Wiring Diagrams for Reference Si39 502A 262 Appendix BEVQ71M 100M 125MVE 3D044901A Notes...

Page 285: ...Piping Installation Point Si39 502A 274 Appendix...

Page 293: ...Method of Replacing The Inverter s Power Transistors and Diode Modules Si39 502A 282 Appendix...

Page 307: ...Si39 502A iv Index...