4. Fixing stage

As the toner image transferred onto the paper in the transfer stage is held to the paper only by

the static electricity, even a light touch will smear the image.

The toner particles are fused to the paper to make an permanent image by applying pressure

and heat to the paper and the toner.

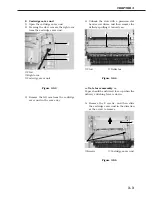

Step 6: Fixing

Figure 2-4-12

As the toner particles transferred onto the paper are held to the paper by the positive charge

applied to the back of the paper, they may be dispersed at fixing.

This printer applies the negative DC voltage to the fixing film via the pressure roller shaft.

The negative charge is applied to the paper surface by the fixing film before the paper reaches

the fixing heater. This improves the adhesion force of the toner particles to the paper and pre-

vents dispersion of the toner particles.

This printer utilizes an on-demand method which uses fixing film with small heat capacity.

This method can heat the roller quickly and does not require the power supply to the fixing

heater at standby mode. Therefore, the wait time is reduced to eight seconds or less, and the

energy can be saved.

The fixing film is a cylindrical polyimide film. The surface is coated with fluorine to prevent

offset.

CHAPTER 2

2 - 28

Fixing film

Fixing heater

Paper

Toner

Pressure roller

Fixing film

Toner

Paper

Pressure roller