31

cab Produkttechnik GmbH & Co KG

A3-2 / A3 / A4 / A6

1

2

5. Connecting the Printer

5. Connecting the Printer

CAUTION !

Make sure the printer is located where the unit or the operator cannot

come in contact with water. Otherwise it could cause damage to the

printer.

Connection to Power Supply

The printer is equipped with a wide range power unit (100-240V~), so it is

possible to use the printer both with a voltage of 230V~/50 Hz and with a

voltage of 115V~/60 Hz without making changes to the printer.

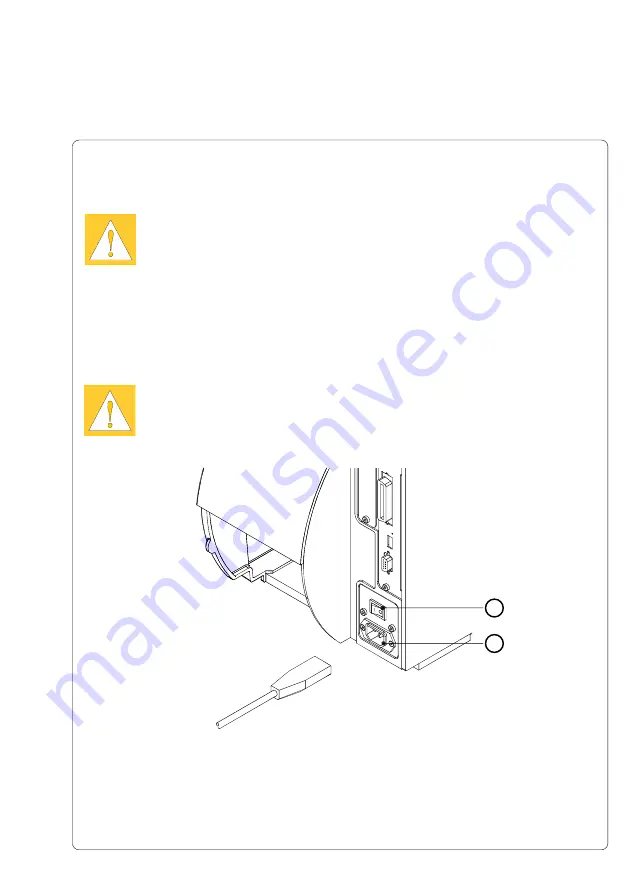

CAUTION !

Make sure the power switch (1) is in position "O" (OFF) before

connecting the printer to a power supply !

Fig. 5a Power supply

Insert the power cable supplied in the accessories carton into the power supply

connector (

2

) and contact the cable to a grounded outlet.

Summary of Contents for a3-2

Page 1: ...Edition 10 04 Thermal direct Printer Transfer Printer Operator s Manual...

Page 77: ...77 cab Produkttechnik GmbH Co KG A3 2 A3 A4 A6 A B D C E F 9 Test Options Fig 9l Status Print...

Page 83: ...83 cab Produkttechnik GmbH Co KG A3 2 A3 A4 A6 9 Test Options Fig 9o Printhead Profile...

Page 87: ...87 cab Produkttechnik GmbH Co KG A3 2 A3 A4 A6 9 Test Options Fig 9s Test Grid...