7

Placing the heating system in operation

Logano plus GB312 – 6 720 806 273 (2013/01)

32

Fig. 37 Pressure/temperature gauge

▶ Top up heating water or drain off water via the drain & fill valve until

the required operating pressure has been reached.

▶ While filling, bleed the heating system via the radiator bleed valves.

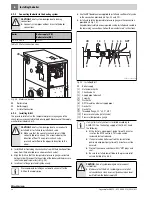

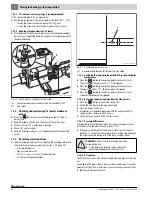

Fig. 38 Topping up heating water or draining off heating water via the

drain & fill valve

[1]

Fill and drain valve

7.2

Checking for leaks

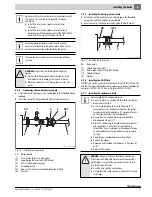

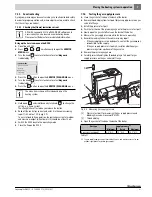

Before commissioning, all new sections of gas piping must be checked

for external leaks.

▶ Check the new section of piping for external leaks up to the sealed

joint where it directly joins the gas valve.

If the leak test identifies a leak, use a non corrosive soap / leak

detector on all joints to check for additional leaks. The agent must be

approved for gas leak testing. Do not apply the agent to electrical

connecting cables.

▶ Confirm completion of the leakage test in the commissioning report.

7.3

Checking appliance equipment

7.4

Checking the air intake and outlet openings and flue

connector

▶ Check whether the air intake and outlet openings comply with local

codes and those of your gas supplier.

▶ Check that the flue connector complies with the applicable

regulations (

Section 6.8, page 22).

▶ Check that the flue pressure does not exceed the available pressure

of 0.4 inches W.C. (100 Pa).

CAUTION:

Health risk from contaminated drinking

water!

▶ Observe all country-specific regulations and

standards regarding the prevention of drinking water

contamination.

The boiler is equipped with a low-pressure sensor. This

prevents the boiler from starting up if the pressure is

below approx.

9 psi

.

7 747 010 720-24.2RS

7 747 010 720-25.1RS

1

DANGER:

Risk of explosion from leaking gas lines and

gas connections!

▶ Use soap solution to carry out a proper leak test.

DANGER:

Risk of system damage due to short-circuits!

▶ Prior to checking for leaks, cover areas at risk, e.g.

the internal water pressure sensor and the return

temperature sensor in the boiler return.

▶ Never spray or let leak detection agent drip onto

cable entries, plugs or electrical cables/leads.

Gas type

Settings

Natural gas (gas

type A)

Delivered factory-set ready for use. The gas valve is

set and sealed.

Calorific value for 60 °F, 30 ins Hg

Set to 1075 BTU/FT

3

Table 15 Settings

CAUTION:

Risk of boiler damage from the wrong gas

type!

The burner may be used only with the type of gas

specified for it.

▶ Check whether the actual gas type is the same as that

stated on the data plate.

DANGER:

Danger of fatal accident due to poisoning!

Insufficient ventilation may cause dangerous flue gas

leaks.

▶ Never close off or reduce the size of air intake and

outlet openings.

▶ Never operate the boiler unless faults are rectified

immediately.

▶ Inform the system user in writing of the problem and

associated danger.