9

Heating system inspection

Logano plus GB312 – 6 720 806 273 (2013/01)

41

9.2

General operations

The following operations are not described in any further detail in this

document. They have to be carried out nevertheless:

▶ Checking the general condition of the heating system.

▶ Visual inspection and function check of the heating system.

▶ Checking the air supply and flue pipes for proper functioning and

safety.

▶ Checking all gas and water piping for signs of corrosion.

▶ If necessary, replace any corroded pipes.

▶ Check the charge pressure of the expansion vessel.

▶ Annually check the concentration of any additives used in the water.

9.3

Checking the flue system, including the combustion

air supply, air inlet/outlet openings

Check the flue system, including air supply system and any air inlet/

outlet openings. Immediately rectify any deficiencies identified. Make

sure that the combustion air supply and the air inlet/outlet openings are

not blocked at any point.

9.4

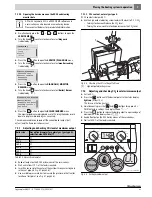

Checking the heating system operating pressure

▶ Check the system pressure.

If the temperature/pressure gauge needle drops below the minimum

pressure marker, the operating pressure is too low. The heating

system must be topped up.

Fig. 52 Pressure/temperature gauge

▶ Fill water via the drain & fill valve.

▶ Bleed the boiler by carefully opening the safety valve or an automatic

vent (accessory) on the B-kit when the boiler circulation pump is

running.

▶ Bleed the heating system via the purge valves.

▶ Check the operating pressure again.

▶ Record the amount of water added in the operator's log.

▶ Refit boiler front panel (

Fig. 5, page 13).

9.5

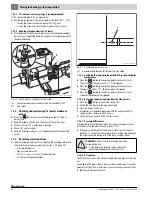

Measuring the carbon dioxide content

▶ Insert the sensor into the center of the gas flow through the testing

hole in the vent pipe.

▶ Record the flue gas readings.

If the CO

2

content differs from the specified level by 0,5 %

(

Sections 7.11 to 7.13, pages 35 to 36), adjust the burner as

described in Sections 7.11 to 7.13, pages 35 to 36.

Establish an operating pressure of at least 15 psi.

CAUTION:

Health risk from contaminated drinking

water!

▶ Observe all country-specific regulations and

standards regarding the prevention of drinking water

contamination.

CAUTION:

Risk of system damage from frequent

topping up!

If you have to top up the heating water frequently, the

heating system may suffer damage from corrosion or

scaling, depending on the water quality (see operator's

log in

"7747010721_GB312_Water Quality

Requirements.pdf"

).

▶ Bleed the heating system while filling.

▶ Check the heating system for leaks.

▶ Check that the expansion vessel functions properly.

Read off the operating pressure from the controller (e.g.

"P15" means 15 psi).

7 747 010 720-24.2RS