10

Troubleshooting

Logano plus GB312 – 6 720 806 273 (2013/01)

53

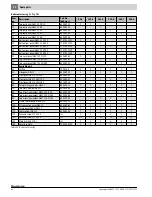

10.2.2 Fault displays

Type

1)

Display code Fault code

Cause

Description

Testing sequence/

Cause

Measure

K

2E

207

The water pressure is < 8.7

psi (0.6 bar).

-

Is the pressure in the

heating system at least

14.5 psi (1 bar).

Adjust operating

pressure.

K

2U

565

Difference between supply

and return temperature too

great.

(>72 °F; >40 K)

Heat exchanger cut-out

due to excessive

temperature spread.

System configuration

problems.

Check system

configuration.

V

2U

575

Boiler sensor/ISTB sensor.

The maximum

permissible temperature

at the ISTB has been

reached.

Check water flow.

Check water flow.

Check orientation of

check valve (direction of

flow).

Check boiler sensor/

STB.

V

3C

537

No speed signal.

The SAFe is not receiving

a speed signal even

though the fan is

supposed to be running.

Check connecting cables

between SAFe and fan for

poor contact, breaks and

damage.

Check connectors on

SAFe and fan.

Establish good electrical

contact. Replace cable if

necessary.

If fan has power (but is

not running) replace fan.

If fan has no power,

replace the SAFe

V

3C

538

Fan speed too slow.

The actual speed

detected is slower than

the set speed.

Dirt in fan.

Fan defective.

Clean fan if necessary.

Replace fan.

V

3C

540

Fan speed too fast.

The actual speed

detected is faster than

the set speed.

Check PWM signal/SAFe

connecting cable for poor

contact, breaks and

damage.

Check connectors for

damage.

Establish good electrical

contact. Replace cable if

necessary.

Replace fan.

V

4A

520

Boiler safety temperature

limiter (STB).

The supply temperature

has reached 200 °F

(93 °C) (cut-out

temperature of boiler

temperature limiter).

Fault can only occur as a

result of faults in the

system configuration

(e.g. only in 2-boiler

systems).

Check system

configuration. Check

orientation of check

valve (direction of flow).

V

4U

521

Temperature difference at

twin boiler sensor too great.

Temperature difference

between supply

temperature sensors 1

and 2 too great

(deviation of > 9 °F/2 s;

5 K/2 s).

Check connectors on

boiler temperature sensor

and SAFe for dirt/

damage.

Check boiler temperature

sensor resistance against

sensor characteristic/

visually check plug on

temperature sensor.

Check the voltage at the

boiler temperature sensor

against the table (SAFe

document).

Clean contacts/replace

connecting cable if

necessary.

If there are

discrepancies in the

sensor readings or the

connector is defective,

the temperature sensor

must be replaced.

Replace SAFe if there

are discrepancies.

Table 23 Fault displays

1) V = interlocking; B = inhibiting; BC = operating code