7

Placing the heating system in operation

Logano plus GB312 – 6 720 806 273 (2013/01)

35

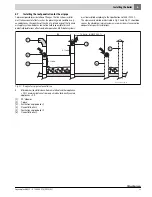

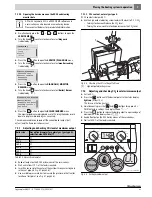

7.10.2 Opening the Service menu on the RC35 and viewing

monitor data

▶ Simultaneously press the

+

+

buttons to open the

SERVICE MENU

.

▶ Turn the knob

counter-clockwise to select

diagnosis

(indicated by

).

▶ Press the

button to open the

SERVICE / DIAGNOSIS

menu.

▶ Turn the knob

counter-clockwise to select

monitor reading

(indicated by

).

▶ Press the

button to open the

DIAGNOSIS / MONITOR

READING

menu.

▶ Turn the knob

counter-clockwise to select

Boiler / Burner

(indicated by

).

▶ Press the

button to open the

BOILER / BURNER

menu.

The monitor readings are displayed as a list. Turning the knobs scrolls

down to display more readings as necessary.

These menus enable you to read off the current boiler output (set/

actual) and the flame ionization current.

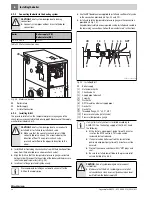

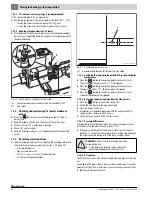

7.11

Adjusting and checking CO

2

level at maximum output

▶ Read off output on the RC35 or by means of the service keys.

▶ Wait until at least 70 % of the load is reached.

▶ Insert the sensor into the center of the gas flow through a testing hole

in the vent pipe (

Fig. 47, page 36).

▶ Use a suitable pressure tester to measure the pressure in the flue (for

location of test point, see Fig. 47, page 36).

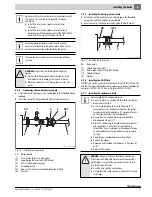

7.11.1 CO

2

content, natural gas type A

If CO

2

content is below 8,5 %.

▶ Use the high-output adjusting screw to adjust the level to 9,1 % CO

2

.

– Turning clockwise will reduce the CO

2

level.

– Turning the screw counter-clockwise increases the CO

2

level.

Fig. 44 Checking the CO

2

setting at full load

[1]

High-output adjusting screw

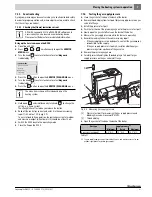

7.12

Adjusting and checking CO

2

level at minimum output

▶ Set to 30 %.

▶ Press the

button until the decimal point in the status display

lights up

(at least 2 s).

This turns on the flue gas test.

▶ Simultaneously press the

and

buttons for approx. 5 s.

With the factory settings, the display shows "

".

▶ Press the

button to reduce the boiler output to a percentage of

maximum until the display shows "

".

▶ Read off output on the RC35 or by means of the service keys.

▶ Wait until 30 % of the load is reached.

Fig. 45 Setting medium output

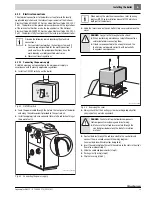

A PC with Logamatic ECO -Soft4000/EMS software and

a service key can also be used as a monitoring device.

Please contact Buderus for more detailed information.

Boiler size

Gas orifice diameter for natural gas (gas type A),

calorific value 1075 Btu/ft

3

90-4

17

120-4

17

160-5

17

200-6

17

240-7

17

280-8

17

Table 16 Gas orifice diameter

SERVICE MENU

quick operation

settings

diagnosis

servicing

SERVICE|DIAGNOSIS

function test

monitor reading

diagnosis

servicing

B

DIAGNOSIS|MON.READING

Boiler/Burner

domestic hot water

heating circuit 1

bus users

B

7 747 010 720-52.2RS

1

7 747 010 720-42.2RS

90

130

100

120

110

Eco

140

Aut

90

110

130

150

170

190

Aut