6

Installing the boiler

Logano plus GB312 – 6 720 806 273 (2013/01)

20

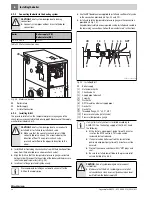

6.6

Installing the wall penetration for the air pipe

To prevent possible recirculation of flue gas, the flue system installer

must take account of effects such as the prevailing wind conditions, e. g.

any eddy zones, the specifics of the site, etc. in the design of the flue and

air supply systems. Buderus can not be held responsible for such

potentially deleterious effects on boiler operation. Multi-boiler systems

must be installed according to the specifications of ANSI Z223.1.

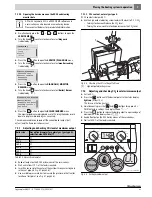

The clearances detailed or illustrated in Fig. 12 and Fig. 16 should be

seen as the absolute minimum and may in some circumstances not be

adequate for specific installations.

Fig. 16 Design of air pipe wall penetration

A

Minimum vertical distance from air intake of another

appliance = 3 ft.; with directly vented appliances, the flue outlet

can be positioned level with the appliance's own air intake

(observe minimum horizontal separation of 4 ft).

[1]

Flue outlet boiler 1

[2]

Inner wall centering and retaining plate

[3]

Boiler sealer

[4]

Outer wall retaining plate

[5]

T-piece or

[6]

90° elbow

[7]

Air intake boiler 1

[8]

Flue outlet boiler 2

[9]

Air intake boiler 2

2

1

4

3

5

7

6

8

9

4 ft min.

10 ft min. (ANSI Z223.1)

4 ft min.

12 in min.

12 in min.

6 720 647 031-01.1T

3 ft min.

A