9

Heating system inspection

Logano plus GB312 – 6 720 806 273 (2013/01)

49

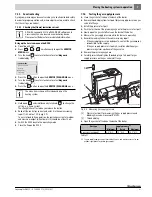

9.11

Servicing and maintenance logs

The inspection and maintenance logs can also be used as templates.

▶ Sign and date the completed inspection work.

If any condition requiring maintenance work is identified

in the course of inspection, that work must be carried out

as required.

Service work

Page

Maximum load

Minimum load

Maximum load

Minimum load

1.

Check general condition of heating system (visual inspection and

function check)

-

2.

Checking the gas and water-bearing system components for:

internal leaks

Visible signs of corrosion

-

signs of ageing

-

3.

Check concentration of additives in heating water

(

see additive manufacturer’s documentation and "Water quality

4.

Checking the heating system operating pressure

41

5.

Check air intake and outlet openings and flue connector

32

6.

Record readings taken:

36

Pressure differential

____in W.C.

____in W.C.

____in W.C.

____in W.C.

Aggregate flue gas temperature t

A

________ °F

________ °F

________ °F

________ °F

CO

2 level or oxygen content

(O

2

)

________ %

________ %

________ %

________ %

Determine extent of contamination:

Clean the burner and heat exchanger as necessary

CO content, free of air

______ ppm

______ ppm

_____ ppm

______ ppm

7.

Carry out function checks:

37

Check ionization current

________ μA

________ μA

________ μA

________ μA

8.

Checking for leaks during operation

38

9.

Check that the controller settings are as required (

technical

documentation for controller)

–

10.

Final check of servicing work

–

Confirmation of properly completed servicing

Company stamp/Date/Signature

Table 20 Servicing and maintenance logs