6

Installing the boiler

Logano plus GB312 – 6 720 806 273 (2013/01)

25

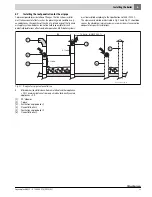

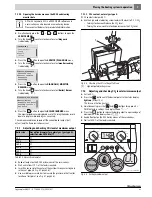

6.9.4

Connecting the central heating supply

▶ Install and seal the heating system supply pipe to the threaded flange

supplied.

▶ Insert the seal in the flange joint and tighten the bolts evenly.

Fig. 25 Installing the supply pipe

VK

Boiler supply

[1]

Safety valve (pressure relief valve)

[2]

Supply pipe (external with NPT thread)

[3]

Pressure/temperature gauge

[4]

Threaded flange

[5]

Non-return check valve (observe direction of flow)

[6]

Washer

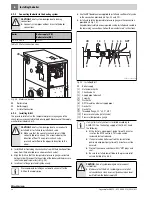

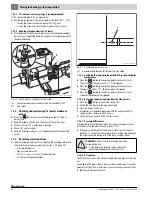

6.9.5

Installing the heating system return

▶ Install and seal the heating system return pipe in the threaded

connection on the threaded flange supplied.

▶ Insert the seal in the flange joint and tighten the bolts evenly.

Fig. 26 Installing the return pipe

RK

Boiler return

[1]

Thread on boiler return

[2]

Return pipe (external with NPT thread)

[3]

Threaded flange

[4]

Washer

6.9.6

Installing the DHW Tank

A DHW Tank can be connected to the connections VK (after the B-kit)

and RK. The required cylinder charging pump can be controlled by the

control unit MC10 + BC10 (see instructions MC10 + BC10).

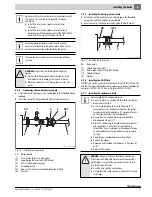

6.9.7

Installing the condensate drain

Do not install the safety valve (pressure relief valve) until

the leak test (

Section 6.10 page 26) has been

completed.

▶ Install the safety valve (pressure relief valve)

vertically.

▶ Install the safety valve (pressure relief valve) in

accordance with the requirements of the ANSI/ASME

Boiler and Pressure Vessel Code, Section IV.

We recommend installing a water filter (Y-strainer,

accessory) externally to the boiler return RK on site to

prevent contamination of the boiler by the water.

Observe the local regulations for connection of boiler

systems.

DANGER:

Risk of fire from flammable materials or

liquids.

▶ Do not store flammable materials or liquids in the

immediate vicinity of pipes that carry hot water.

▶ Maintain a clearance of 2" from pipes carrying hot

water.

VK

6

2

3

1

5

4

NPT

7 747 010 720-04.1RS

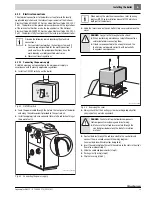

Notes regarding the condensate drain.

▶ Correctly drain the condensate that forms inside the

boiler and in the flue.

▶ Use a suitable siphon to drain condensate that

accumulates in the flue before it reaches the boiler

(maximum distance to boiler: 6 ft). Condensate must

not be allowed to flow into the appliance.

▶ Ensure that the condensate drain is adequately

dimensioned (at least ¾ ").

▶ Drain the condensate in accordance with local rules

and regulations. Consul local authority having

jurisdiction. Some state require the condensate to be

neutralized before entering public sewers or septic

systems.

▶ Also observe any applicable local regulations.

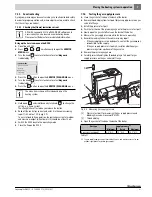

▶ Remove the siphon.

▶ Undo cap and fill siphon with approx. 0.3 gallons of

water.

▶ Reinstall the siphon.

DANGER:

Danger of fatal accident due to poisoning!

If the trap is not filled with water or other connections

are left open, escaping flue gas can place lives at risk.

▶ Fill the trap with water.

▶ Seal the trap and flue connections.

▶ Ensure that the sealing washer with gasket is seated

in the cap.

RK

NPT

2

1

4

3

7 747 010 720-81.1RS