3. INSTALLATION

RH-9820

25

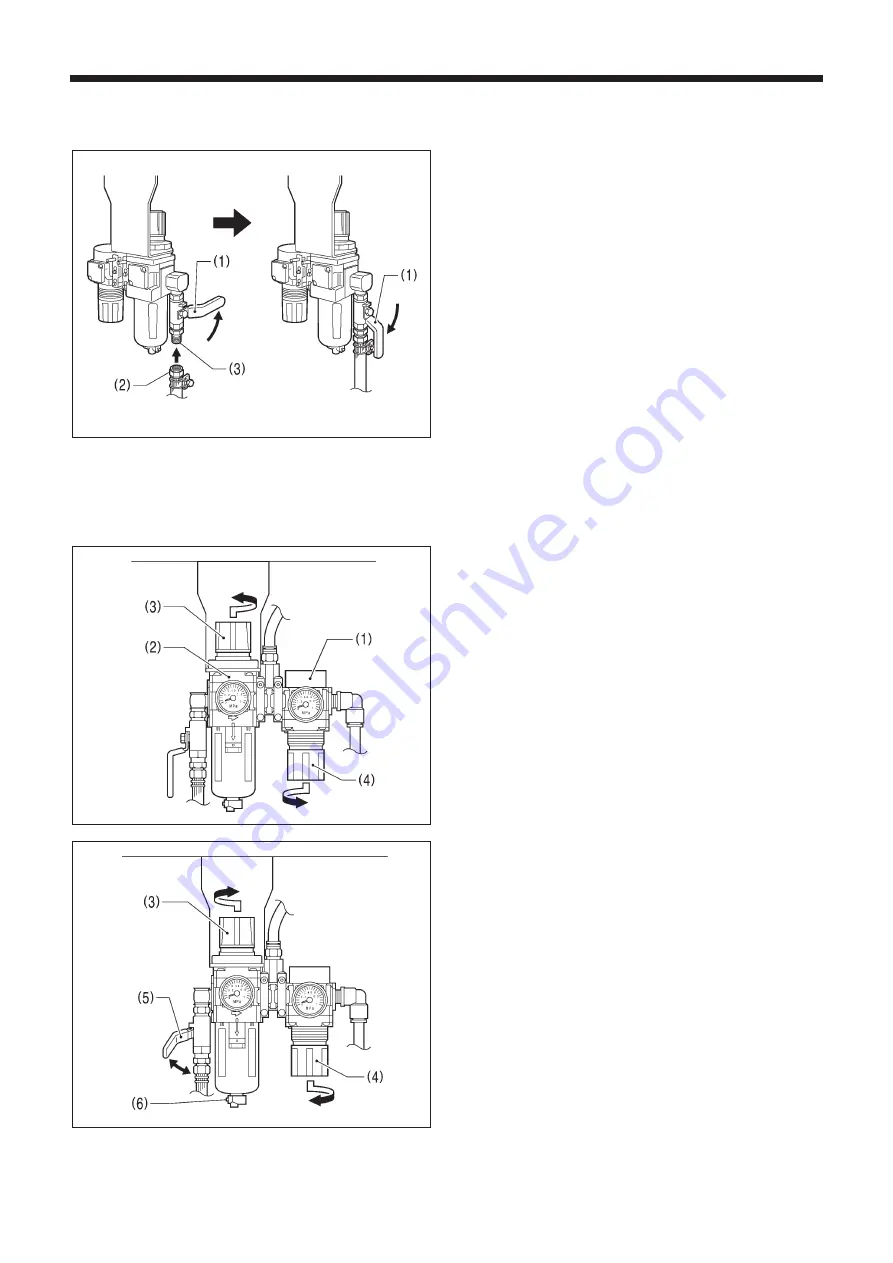

3-15. Installing the air hose

Connect the air hose coming from the compressor to the air unit which is installed underneath the table.

1. Close the cock (1).

2. Turn the nut (2) at the end of the air hose and connect it to

the valve (3).

3. Open the cock at the compressor.

* Check that no air is leaking from the valve connection.

4. Open the cock (1).

(The meter pointer will turn clockwise.)

5. Adjust the air pressure.

NOTE:

Turn the cock (1) gently to open it. If this is not done, the

air cylinder may operate too suddenly.

Close Open

3-16. Adjusting the air pressure

Adjust the hammer pressure adjustment regulator (1) to the minimum pressure setting which will allow cutting of the article

being sewn.

To set to the standard pressure, adjust the main regulator (2) to 0.5 MPa.

<Increasing the air pressure>

1. Lift up the knob (3) of the main regulator (2) and turn it

gently to adjust the pressure.

* When the knob (3) is turned in the direction of the arrow,

the air pressure will increase.

2. Pull down the knob (4) of the hammer pressure

adjustment regulator (1) and turn it gently to adjust the

pressure.

* When the knob (4) is turned in the direction of the arrow,

the air pressure will increase.

NOTE:

The hammer pressure adjustment regulator (1) is already

adjusted to a pressure of 0.4 MPa. Do not increase the

pressure if it is not necessary to do so. If the pressure is

too high, the sharpness of the knife will deteriorate and

the knife may become damaged.

<Decreasing the air pressure>

1. Close the air cock (5). (The pointer will stay at the high

position on the scale.)

2. Press the button (6).

The air pressure inside the bowl will be released and the

pointer will move down.

3. To decrease the air pressure, lift up the knob (3) or pull

down the knob (4) and turn it in the direction of the arrow.

4. Open the cock (5).

Air will enter the bowl and the pointer will move.

5. Repeat steps 1 to 4 until the desired air pressure is

obtained.

Close

Open

0374B

0375B

0376B