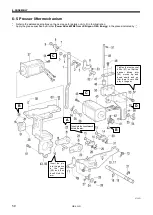

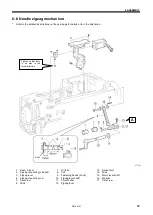

6. ASSEMBLY

HE-800B

56

C

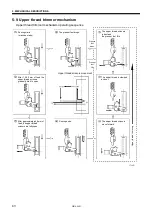

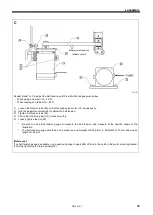

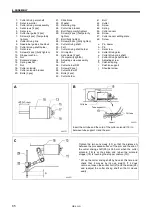

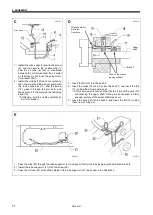

Repeat steps1 to 3 to adjust the belt tension until it is within the ranges given below.

・

When using a new belt: 40 - 45 N

・

When reusing an old belt: 30 - 45 N

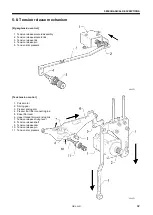

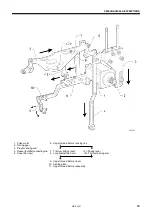

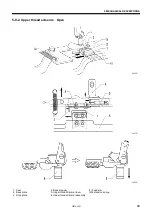

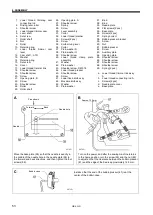

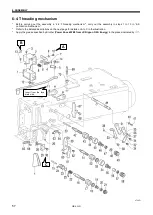

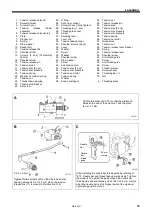

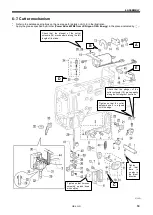

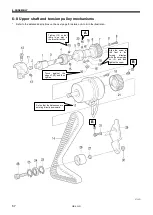

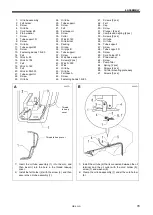

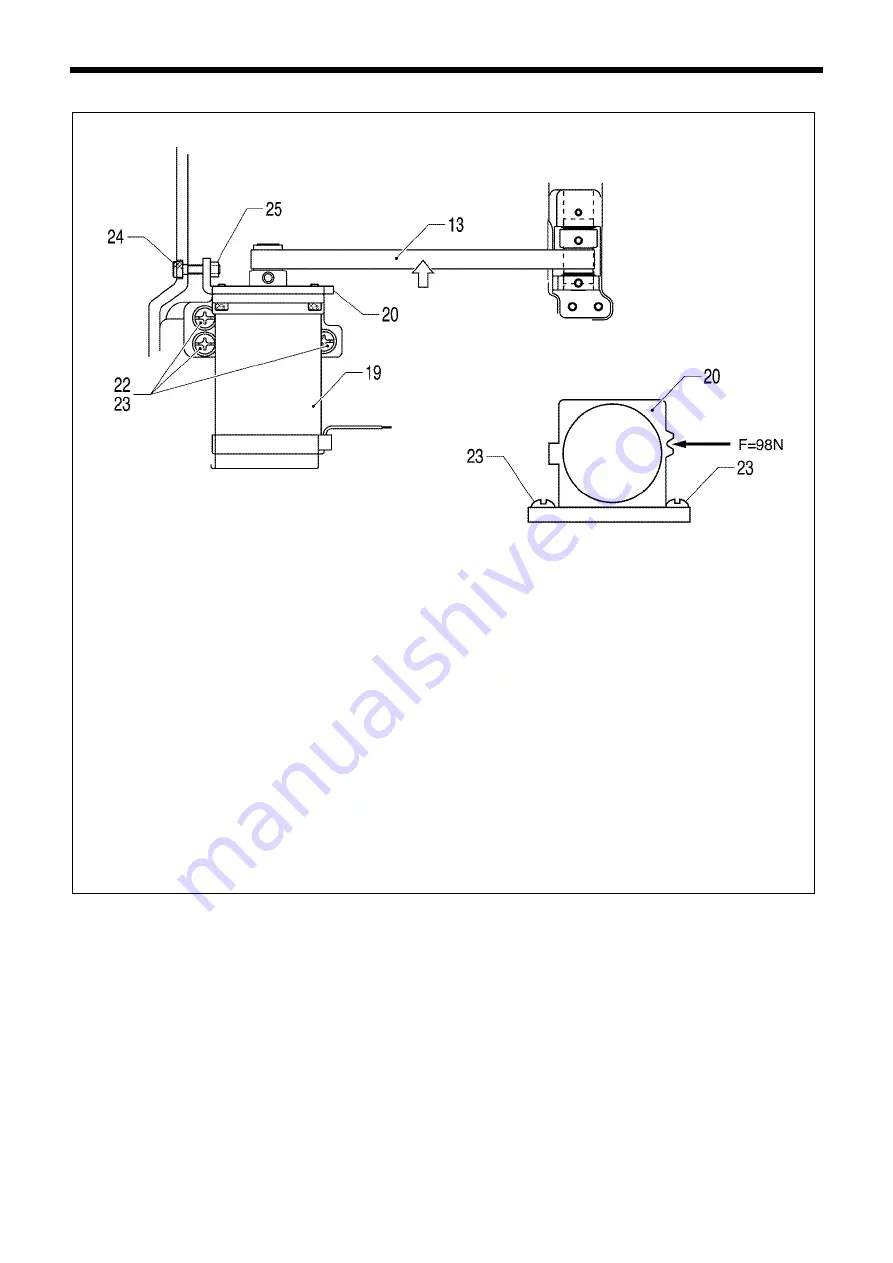

1) Loosen the three screws (23) so that the feed pulse motor (19) moves easily.

2) Use the adjustment screw (24) to adjust the belt tension.

3) Tighten the three screws (23).

4) Check that the timing belt (13) moves smoothly.

5) Loosely tighten the nut (25).

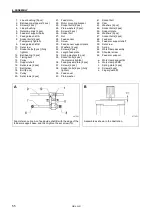

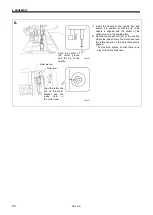

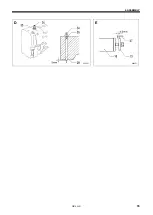

* Be sure to use a belt tension gauge to measure the belt tension, and measure at the position shown in the

illustration.

* The belt tension gauge should be set to measure a unit weight of 0.25 gf/cm, a belt width of 10 mm and a span

length of 169 mm.

[Reference]

If no belt tension gauge is available, use a push pull gauge to apply 98N of force to the notch in the motor mounting bracket

(20) while tightening the three screws (23).

0675D

Measurement position

(Middle of belt)

Summary of Contents for HE-800B

Page 7: ...v HE 800B Oil tank accessory 4732M 4731M 4730M ...

Page 75: ...6 ASSEMBLY HE 800B 66 D E 0688D 0690D ...

Page 126: ...9 ELECTRIC MECHANISM HE 800B 117 Power PCB Cutter PCB LCD panel PCB 0831D 0768D 0769D ...

Page 133: ...9 ELECTRIC MECHANISM HE 800B 124 0851D ...

Page 134: ...9 ELECTRIC MECHANISM HE 800B 125 0852D ...

Page 135: ...9 ELECTRIC MECHANISM HE 800B 126 0853D ...

Page 177: ...MEMO 168 HE 800B ...

Page 178: ...SERVICE MANUAL 2014 Brother Industries Ltd All Rights Reserved HE 800B I3061003D 2014 03 D 1 ...