7. ADJUSTMENT

HE-800B

106

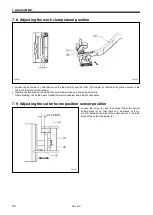

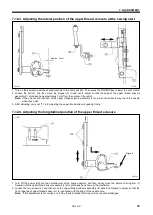

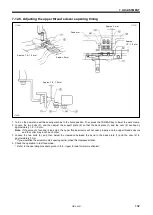

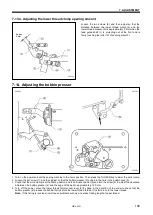

7-13-4. Adjusting the lower thread clamp opening amount

Loosen the two screws (6), and then adjust so that the

distance between the lower thread clamp (4) and the

lower thread presser (5) is approximately 5 mm when the

feed guide shaft (1) is projecting out at the front and is

firmly touching the roller (3) of opening plate (2).

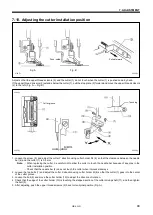

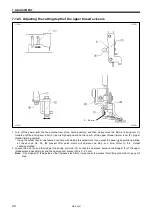

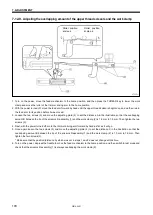

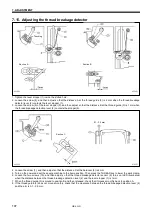

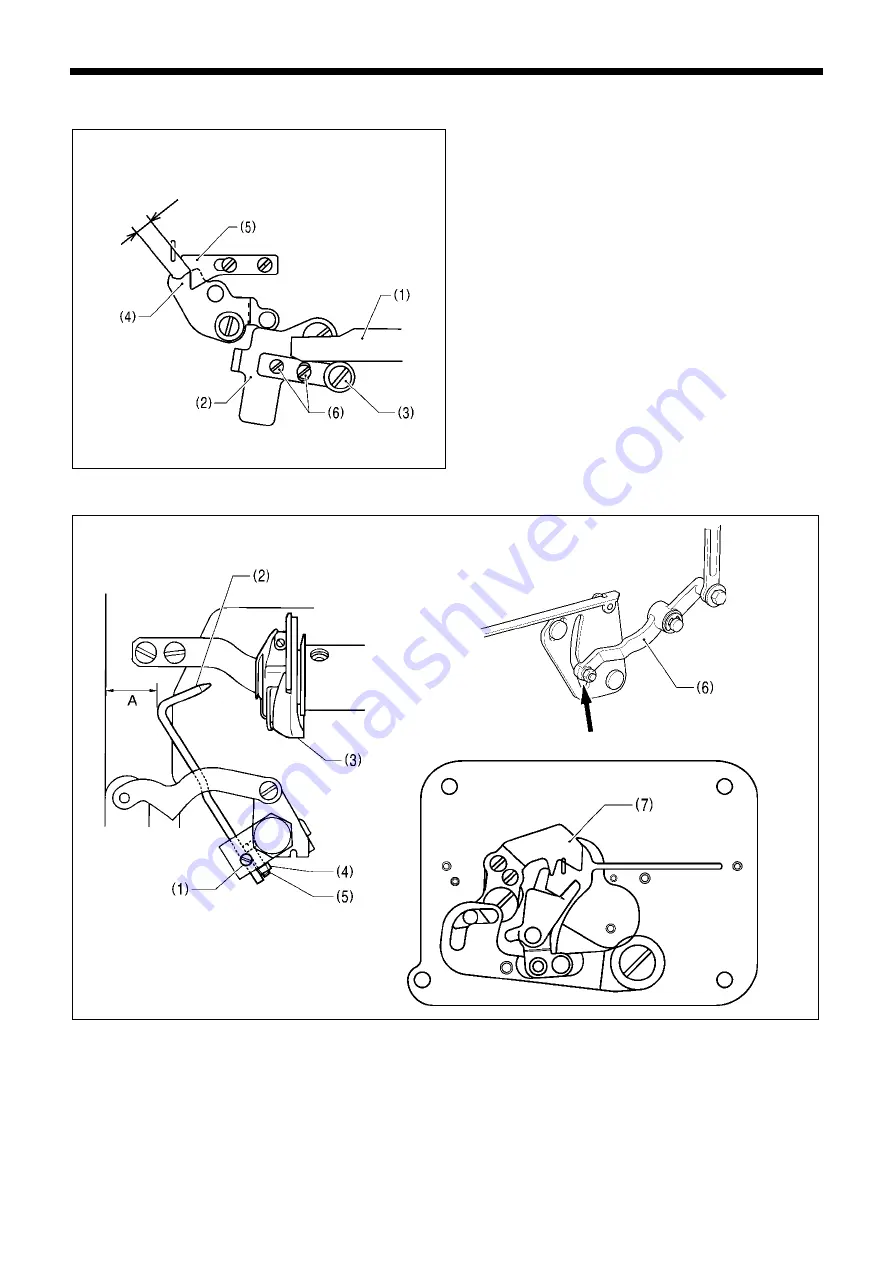

7-14. Adjusting the bobbin presser

1. Turn on the power and set the sewing machine to the home position. Then press the THREAD key to lower the work clamp.

2. Loosen the set screw (1), and then adjust so that the bobbin presser (2) goes into the hole in the bobbin case (3).

3. Check that the work clamp is at the home position, and then loosen the nut (4) and turn the screw (5) to adjust the clearance

A between the bobbin presser (2) and the edge of the bed to approximately 12.5 mm.

4. Turn off the power, move the lower thread trimmer cam lever (6) by hand in the direction of the arrow to check that the

bobbin presser (2) presses the bobbin firmly before the lower thread retainer (7) starts to hold the lower thread.

Note:

If this timing is reversed, it will cause problems such as an excess trailing length of upper thread.

4351Q

4352Q

4350Q

3989Q

Approx.

5 mm

Summary of Contents for HE-800B

Page 7: ...v HE 800B Oil tank accessory 4732M 4731M 4730M ...

Page 75: ...6 ASSEMBLY HE 800B 66 D E 0688D 0690D ...

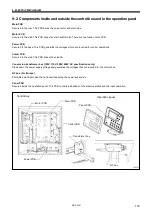

Page 126: ...9 ELECTRIC MECHANISM HE 800B 117 Power PCB Cutter PCB LCD panel PCB 0831D 0768D 0769D ...

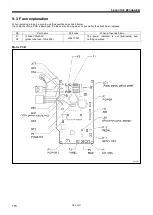

Page 133: ...9 ELECTRIC MECHANISM HE 800B 124 0851D ...

Page 134: ...9 ELECTRIC MECHANISM HE 800B 125 0852D ...

Page 135: ...9 ELECTRIC MECHANISM HE 800B 126 0853D ...

Page 177: ...MEMO 168 HE 800B ...

Page 178: ...SERVICE MANUAL 2014 Brother Industries Ltd All Rights Reserved HE 800B I3061003D 2014 03 D 1 ...