TROUBLESHOOTING

Main

te

nan

ce

a

nd

Tr

oubl

es

hoo

ting

Appendix

A-23

A

2

If the machine stops operating correctly, check the following possible problems before requesting service.

You can solve most problems by yourself. If you need additional help, the Brother Solutions Center offers

the latest FAQs and troubleshooting tips. Visit us at “ http://solutions.brother.com ”.

If the problem persists, contact your dealer or the nearest authorized service center.

Frequent troubleshooting topics

Detailed causes and remedies for common troubleshooting topics are described below. Be sure to refer to

this before contacting your dealer.

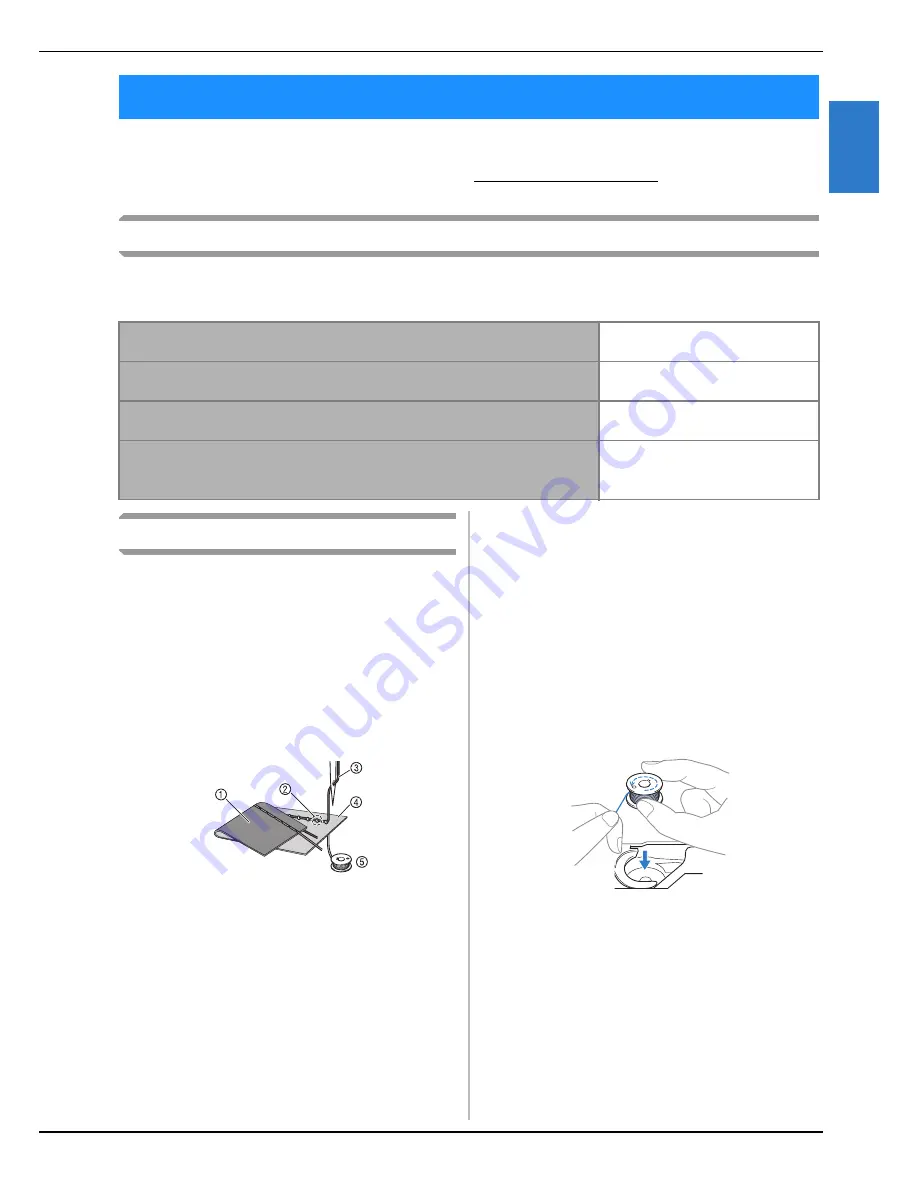

Upper thread tightened up

■

Symptom

*

The upper thread appears as a single continuous

line.

*

The lower thread is visible from the upper side of the

fabric. (Refer to the illustration below.)

*

The upper thread has tightened up, and comes out

when pulled.

*

The upper thread has tightened up, and wrinkles

appear in the fabric.

*

The upper thread tension is tight, and the results do

not change even after the thread tension is adjusted.

a

Lower side of fabric

b

Lower thread visible from upper side of fabric

c

Upper thread

d

Upper side of fabric

e

Lower thread

■

Cause

Incorrect lower threading

If the lower thread is incorrectly threaded, instead of

the appropriate tension being applied to the lower

thread, it is pulled through the fabric when the

upper thread is pulled up. For this reason, the thread

is visible from the upper side of the fabric.

■

Remedy/check details

Correctly install the lower thread.

a

Turn off the sewing machine.

b

Remove the bobbin from the bobbin case.

c

Place the bobbin in the bobbin case so that

the thread unwinds in the correct direction.

*

Hold the bobbin with your right hand with the

thread unwinding to the left, and hold the end of the

thread with your left hand. Then, with your right

hand, place the bobbin in the bobbin case.

If the bobbin is inserted with the thread unwinding

in the wrong direction, sewing will be done with

an incorrect thread tension.

TROUBLESHOOTING

■

Upper thread tightened up

page A-23

■

Tangled thread on wrong side of fabric

page A-24

■

Incorrect thread tension

page A-26

■

Fabric is caught in the machine and cannot be

removed

page A-27

Summary of Contents for DreamWeaver XE VM6200D

Page 107: ...USEFUL FUNCTIONS Sewing Basics Sewing S 19 S 1 ...

Page 194: ...USING STORED CUSTOM STITCHES S 106 ...

Page 212: ...ATTACHING THE EMBROIDERY FRAME E 18 b Pull the embroidery frame toward you ...

Page 249: ...EMBROIDERY APPLICATIONS Embroidery Embroidering E 55 E 1 ...

Page 280: ...USING THE MEMORY FUNCTION E 86 ...

Page 323: ......