1523.5-0000010 OM

153

5.4.2.12

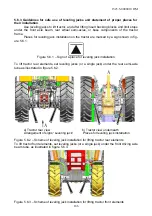

Operation 28. Check / adjustment of clutch control

5.4.2.12.1 Check of clutch control

Check the condition of the expansion tank, main and operating cylinders, hydraulic booster

and pipelines. Brake fluid or oil leakage is not allowed. Clean the control drive and the

clutch control pedal from dirt and outside particles.

Check the clearance between the clutch coupling release bearing and release levers:

when the engine is not running, the total pedal free travel 7 (figures 5.4.16 and 5.4.17)

shall make size E that corresponds to lever 33 shifting at the radius of 105mm for size K.

When pedal 7 is fully depressed, lever 33 shifting at the radius of 105mm shall make not

less than size

Л

.

If necessary, adjust clutch control according to subsection 5.4.2.12.2 “Adjustment of clutch

control” with the help of two people.

ATTENTION: ONLY DEALERS ARE ALLOWED TO ADJUST AND BLEED CLUTCH

CONTROL!

5.4.2.12.2 Adjustment of clutch control

5.4.2.12.2.1 The rules for adjustment of clutch control

Adjustment of clutch control shall be performed in the following order:

1. Adjustment of clearing “B” (figures 5.4.16 and 5.4.17) between piston 10 and pusher 9

of main cylinder 11:

- set pedal 7 into size “

Д

” by means of bolt 3, tighten nut 4 with the torque from 10 to 16

Nm;

- by screwing and unscrewing yoke 5 try to shift pedal 7 from its initial position to the mo-

ment of touching pusher 9 into piston 10, measured on the center of pedal casing so that it

makes size “

Г

”;

- tighten up nut 8 with the torque from 30 to 50 Nm and splint pin 6.

2. Adjustment of clearing “

И

” (figures 5.4.16 and 5.4.17) between rod 24 of main cylinder

23 and pusher 25 of hydraulic booster 26:

- remove operating cylinder 23 from bracket 13 after taking out pin 15;

- set rod 24 in cylinder 23 into the extreme right position against the stop into cover 20;

- set cylinder 23 into pusher 25 of hydraulic booster 26 until their light contact and by

screwing and unscrewing support 14 match the holes of the support and bracket 13, after

which screw in support 14 for ½ revolutions, set pin 15;

- tighten up nut 19 with the torque from 18 to 30 Nm and splint pin 15.

3. Adjustment of clearing between the clutch coupling release bearing and release levers:

- disconnect link 28 (figures 5.4.16 and 5.4.17) from lever 33 after taking out pin 32;

- unlock yoke 31;

- turn lever 33 contraclockwise against the stop of the release bearing into release levers

and rotating yoke 31 match the holes of the lever and yoke, after which screw it in for

5…5,5 revolutions and connect them with the lever by means of pin 32;

- tighten up nut 30 with the torque from 50 to 70 Nm without letting link 28 turn, splint pin

32.

4. Bleed the hydraulic system of clutch control according to clause 5.4.2.12.2.2 or

5.4.2.12.2.3 of the present operator manual.

5.4.2.12.2.2 Bleeding of the hydraulic system of clutch control with the main and op-

erating cylinders manufactured by RUE “Gomel Works “Hydraulic drive”

Before bleeding, fill tank 1 (figure 5.4.16) of main cylinder 11 with brake fluid.

Bleeding of the hydraulic system shall be performed in the following order:

fill tank 1 with brake fluid up to the mark “MAX”;