1523.5-0000010 OM

32

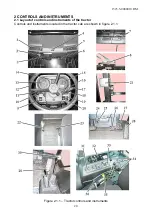

Control panel 16 (figure 2.1.1) allows to carry out manual programming of the indicator

with buttons «

Параметр

» (“Parameter”) and «

Значение

» (“Value”) (see figure 2.8.2), and

also to change the mode of showing data entered on the multifunction display with «

Ре

-

жим

» (“Mode”) button. The “

Режим

” (“Mode”) button is also used to enter a non-fixed pa-

rameter value when programming the device.

The rules on IICP use in the mode of displaying operational parameters and failure mes-

sages on the multifunction display are given below in subsection 2.8.2 “Assignment and

operation principle of II gauges”.

The rules on IICP use in the II programming mode are given below in subsection 2.8.5

“The order of Integrated Indicator programming”.

2.8.2 Assignment and operation principle of integrated indicator gauges

2.8.2.1 Velocity gauge 1 (figure 2.8.1) indicates tractor design speed on a needle indicator.

Design speed exceeds the actual one as tractor skidding is not taken into account.

Velocity gauge 1 is actuated by signals coming from pulse sensors of rotation frequency of

toothed gears of final drives of right and left rear wheels. The speed is indicated in accord-

ance with the signal from the sensor installed on the final drive gear of the wheel rotating

with a less speed.

In case one of the speed sensors is faulty, the integrated indicator shows speed readings

in accordance with the signal coming from the correct sensor. Specific faults of circuits or

speed sensors when the signals from them are missing are displayed in liquid crystal dis-

play as “0” digit, characterizing the fault location – to the right or to the left (see below).

2.8.2.2 Engine speed gauge 2 (figure 2.8.1) indicates rotation frequency of the engine

crankshaft on a needle indicator.

Information on engine speed comes from the electronic control unit. The range of speed

indications is from 0 to 3500 (rpm).

2.8.2.3 RPTO speed gauge 3 (figure 2.8.1) displays the RPTO speed on a light indicator.

The rear PTO speed gauge is actuated by signals coming from a pulse speed sensor, in-

stalled above the toothed washer of the rear PTO reduction unit.

Upon engaging the rear PTO in the mode of “540 min

-1

” the integrated indicator operates

in the following way:

- the annunciator of “540 min

-1

” of rear PTO speed scale range 6 lights up;

- as the speed of the rear PTO shaft end extension reaches 320 min

-1

, a lower

segment of the rear PTO gauge 9 lights up in combination with the annunciator 6.

- as the speed further increases, together with the annunciator 6 the rear PTO indi-

cator segments light up successively from bottom upward in the following order: 8 – 7 – 5

– 4;

- then in the process of the rear PTO operation, the rear PTO speed is displayed on

indicator 3 in accordance with the upper lighting segment of the RPTO according to table

2.3.

When switching the mode “540 rpm economic” the operating order of the rear PTO speed

indicator 6 is the same as for the mode “540 rpm” (an availability to switch on the econom-

ic mode of the RPTO operation is provided only on tractors with GB 24x12).

Upon engaging the rear PTO in the mode of “1000 rpm” the integrated indicator operates

in the following way:

- the annunciator of “540 rpm” of rear PTO speed scale range 6 lights up (figure

2.8.1);

- as the speed of the rear PTO shaft end extension reaches 320 rpm, a lower seg-

ment of the rear PTO gauge 9 lights up in combination with the annunciator 6.

- as the speed further increases, together with annunciator 6 the rear PTO indicator seg-

ments light up successively from bottom upward in the following order: 8 – 7 – 5 – 4;