7

35

_DF115C_DF

135C_O

M

M

_

CO

N_02_G

BI

VZ.

fm

7-

8

F8.1

Maintenance - Electronic System .......................................... 1

1

Maintenance - Electronic System .............................................................. 1

1.1

Maintenance intervals ................................................................................ 2

1.2

Points of maintenance ............................................................................... 5

Batteries (1) ........................................................................................... 5

Generator (2) ......................................................................................... 6

Adjustment of belt tightness ................................................................... 8

Replacement of belt ............................................................................... 9

Checking / adjusting belt tension: ........................................................ 10

If necessary, adjust the belt tension: ................................................... 10

Electric fuses (3) .................................................................................. 11

Type of machine: Conventional electronics ......................................... 11

Switch box .......................................................................................... 11

Fuses in the switching cabinet (B) ....................................................... 12

Relays in the switching cabinet (C) ...................................................... 13

Fuses on the operating panel .............................................................. 14

Relays on the operating panel ............................................................. 15

Type of machine: PLC- electronics ...................................................... 16

Switch box .......................................................................................... 16

Fuses in the switching cabinet ............................................................. 17

Relays in the switching cabinet (C) ...................................................... 19

Fuses on the operating panel .............................................................. 20

F9.0

Maintenance - Points of lubrication ...................................... 1

1

Maintenance- Points of lubrication ............................................................. 1

1.1

Maintenance intervals ................................................................................ 2

1.2

Points of maintenance ............................................................................... 3

Central lubrication (1) ............................................................................ 3

Bearings (2) ........................................................................................... 7

F10.0 Checks, decommissioning ..................................................... 1

1

Tests, check-up, cleaning, stopping ........................................................... 1

1.1

Maintenance intervals ................................................................................ 2

2

General observation ................................................................................... 3

3

Checks by a specialist ............................................................................... 3

4

Cleaning ..................................................................................................... 4

5

Conservation of paver finisher ................................................................... 5

5.1

Downtime up to 6 months .......................................................................... 5

5.2

Downtime between 6 months and 1 year. .................................................. 5

5.3

Re-commissioning: .................................................................................... 5

F11.0 Lubricants and Fuels .............................................................. 1

1

Lubricants and fuels ................................................................................... 1

1.1

Hydraulic oil ............................................................................................... 2

1.2

Instructions referring to the oil types applied ............................................. 3

1.3

Filling volumes ........................................................................................... 4

2

Instructions to change from mineral oil to synthetic oil /

from synthetic oil to mineral oil ................................................................... 8

2.1

Caterpillar drive - planetary gear ................................................................ 8

Summary of Contents for DYNAPAC Svedala Demag DF 115 C

Page 2: ...VALUE QUALITY THE ORIGINAL Your Authorized Dynapac Dealer...

Page 10: ......

Page 18: ......

Page 20: ......

Page 44: ......

Page 58: ......

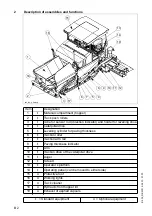

Page 62: ...D 1 4 4 D_1 4_01_GB fm 4 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Page 64: ...D 1 4 6 D_1 4_01_GB fm 6 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Page 96: ......

Page 120: ...D 4 6 24 D_4 6_01_GB fm 24 38 2 2 Error messages...

Page 121: ...D 4 6 25 D_4 6_01_GB fm 25 38...

Page 122: ...D 4 6 26 D_4 6_01_GB fm 26 38...

Page 123: ...D 4 6 27 D_4 6_01_GB fm 27 38...

Page 124: ...D 4 6 28 D_4 6_01_GB fm 28 38...

Page 125: ...D 4 6 29 D_4 6_01_GB fm 29 38 2 3 FMI codes...

Page 134: ......

Page 146: ...E 01 12 E_01_GB fm 12 18 3 Auger extension auger type II Auger_DEM bmp...

Page 152: ......

Page 154: ......

Page 157: ...F 3 0 1 F_3 0_01_GB fm 1 4 F 3 0 Maintenance Conveyor 1 Maintenance Conveyor...

Page 161: ...F 4 1 1 F_4 1_01_GB fm 1 8 F 4 1 Maintenance Auger 1 Maintenance auger sub unit...

Page 168: ......

Page 180: ......

Page 181: ...F 6 0 1 F_6 0_01_GB fm 1 8 F 6 0 Maintenance Hydraulic system 1 Maintenance hydraulic system...

Page 220: ......

Page 221: ...F 10 0 1 F_10 0_01_GB fm 1 6 F 10 0 Checks decommissioning 1 Tests check up cleaning stopping...

Page 226: ......