D 1.4 11

D_1

.4_0

1_G

B.

fm

1

1

-2

2

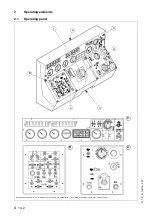

Item Designation

Brief description

20

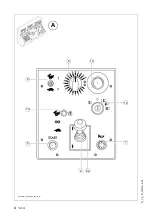

Screed position

A Lift the screed.

B Lock the screed (the position appropriate for inserting the

transportation safeguard of the screed)

C Lower the screed and set it to „Floating position“

m

During paving, the screed must always be in the float-

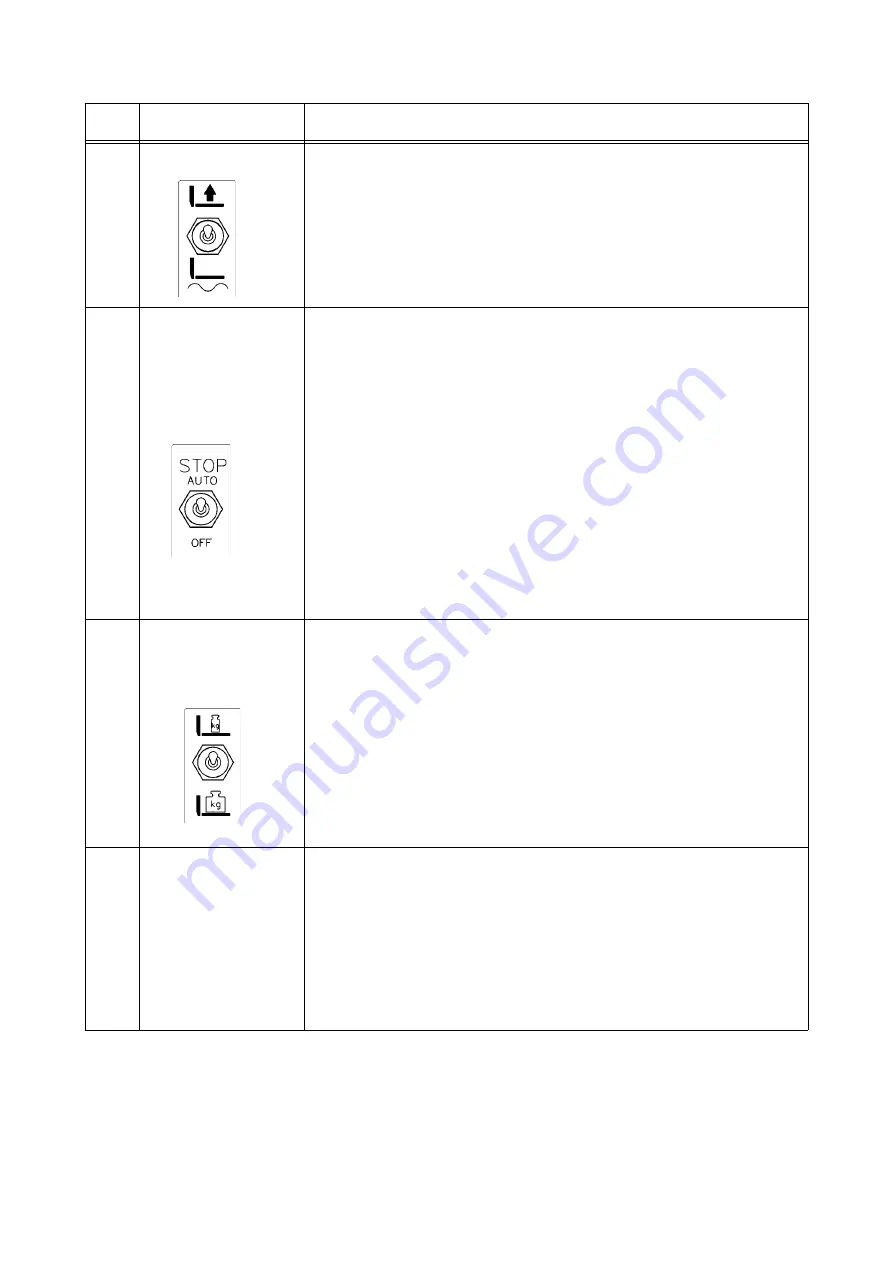

ing position. The same applies to temporary stops and

the case of changing trucks.

21

Screed control

in case of stopped

paver finisher

With this function the hydraulic unit of the screed can be con-

trolled to prevent the lowering of the screed, when the paver

finisher is stopped (temporary stopping).

A automatic- if the drivearm (9) is in central position, in case

of stopping the paver finisher, the screed is controlled by

about 20 bar preliminary pressure.

- Position C can be used for setting the paver finisher, posi-

tion A can be used for paving.

C: switched off- if the drivearm (9) is in central position, in

case of stopping the paver finisher, the screed is only main-

tained in floating position / controlled.

f

In case of transportation or maintenance operations al-

ways insert the mechanical transportation safeguard of

the screed.

22

Screed loading/

offloading

The screed can be thus loaded or offloaded to change the

traction force or compacting.

A: Relieving (screed ‘lighter’)

B: Function Off

C: Charging (screed ‘heavier’)

- With the help of pressure regulating valve (93) the height of

loading and offloading must be adjusted.

- For the function „Stop screed with prestressing“ select posi-

tion A (see switch (21b) and pressure regulator valve

(93a)).

23

Starter switch

„Temporary pres-

sure load when

laying is started“

To start the screed with preselected pressure load.

-

The time limit can be set between 0.5 and 30 sec.

A

This function prevents the floating of the screed, e.g. in

case of temporary stopping or changing trucks.

After the expiry of the preset delay time of the pressure load,

the machine automatically switches to floating position.

A

B

C

A

C

A

B

C

Summary of Contents for DYNAPAC Svedala Demag DF 115 C

Page 2: ...VALUE QUALITY THE ORIGINAL Your Authorized Dynapac Dealer...

Page 10: ......

Page 18: ......

Page 20: ......

Page 44: ......

Page 58: ......

Page 62: ...D 1 4 4 D_1 4_01_GB fm 4 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Page 64: ...D 1 4 6 D_1 4_01_GB fm 6 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Page 96: ......

Page 120: ...D 4 6 24 D_4 6_01_GB fm 24 38 2 2 Error messages...

Page 121: ...D 4 6 25 D_4 6_01_GB fm 25 38...

Page 122: ...D 4 6 26 D_4 6_01_GB fm 26 38...

Page 123: ...D 4 6 27 D_4 6_01_GB fm 27 38...

Page 124: ...D 4 6 28 D_4 6_01_GB fm 28 38...

Page 125: ...D 4 6 29 D_4 6_01_GB fm 29 38 2 3 FMI codes...

Page 134: ......

Page 146: ...E 01 12 E_01_GB fm 12 18 3 Auger extension auger type II Auger_DEM bmp...

Page 152: ......

Page 154: ......

Page 157: ...F 3 0 1 F_3 0_01_GB fm 1 4 F 3 0 Maintenance Conveyor 1 Maintenance Conveyor...

Page 161: ...F 4 1 1 F_4 1_01_GB fm 1 8 F 4 1 Maintenance Auger 1 Maintenance auger sub unit...

Page 168: ......

Page 180: ......

Page 181: ...F 6 0 1 F_6 0_01_GB fm 1 8 F 6 0 Maintenance Hydraulic system 1 Maintenance hydraulic system...

Page 220: ......

Page 221: ...F 10 0 1 F_10 0_01_GB fm 1 6 F 10 0 Checks decommissioning 1 Tests check up cleaning stopping...

Page 226: ......