F 8.1 18

F_8

.1_

01_G

B.

fm

18-

20

F.

A

41

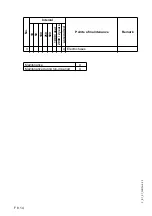

Engine regulation

25

44

Machine drive

1

51

Spray equipment

3

52

Emulsion spray appliance

3

53

Diesel fuel pump

5

54

Flasher

3

55

Headlight (glass fibre reinforced roof)

10

59

Working floodlights (

o

)

15

80

Power supply Master A1

7,5

82

Particle filter (

o

)

3

83

Exhaust equipment (

o

)

3

84

Seat heating

10

85

Windscreen wiper

7,5

86

Reserve

10

88

Power supply Master A1

7,5

Summary of Contents for DYNAPAC Svedala Demag DF 115 C

Page 2: ...VALUE QUALITY THE ORIGINAL Your Authorized Dynapac Dealer...

Page 10: ......

Page 18: ......

Page 20: ......

Page 44: ......

Page 58: ......

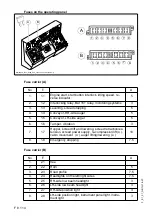

Page 62: ...D 1 4 4 D_1 4_01_GB fm 4 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Page 64: ...D 1 4 6 D_1 4_01_GB fm 6 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Page 96: ......

Page 120: ...D 4 6 24 D_4 6_01_GB fm 24 38 2 2 Error messages...

Page 121: ...D 4 6 25 D_4 6_01_GB fm 25 38...

Page 122: ...D 4 6 26 D_4 6_01_GB fm 26 38...

Page 123: ...D 4 6 27 D_4 6_01_GB fm 27 38...

Page 124: ...D 4 6 28 D_4 6_01_GB fm 28 38...

Page 125: ...D 4 6 29 D_4 6_01_GB fm 29 38 2 3 FMI codes...

Page 134: ......

Page 146: ...E 01 12 E_01_GB fm 12 18 3 Auger extension auger type II Auger_DEM bmp...

Page 152: ......

Page 154: ......

Page 157: ...F 3 0 1 F_3 0_01_GB fm 1 4 F 3 0 Maintenance Conveyor 1 Maintenance Conveyor...

Page 161: ...F 4 1 1 F_4 1_01_GB fm 1 8 F 4 1 Maintenance Auger 1 Maintenance auger sub unit...

Page 168: ......

Page 180: ......

Page 181: ...F 6 0 1 F_6 0_01_GB fm 1 8 F 6 0 Maintenance Hydraulic system 1 Maintenance hydraulic system...

Page 220: ......

Page 221: ...F 10 0 1 F_10 0_01_GB fm 1 6 F 10 0 Checks decommissioning 1 Tests check up cleaning stopping...

Page 226: ......