D 4.6 6

D_4

.6_0

1_G

B.

fm

6

-38

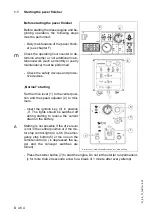

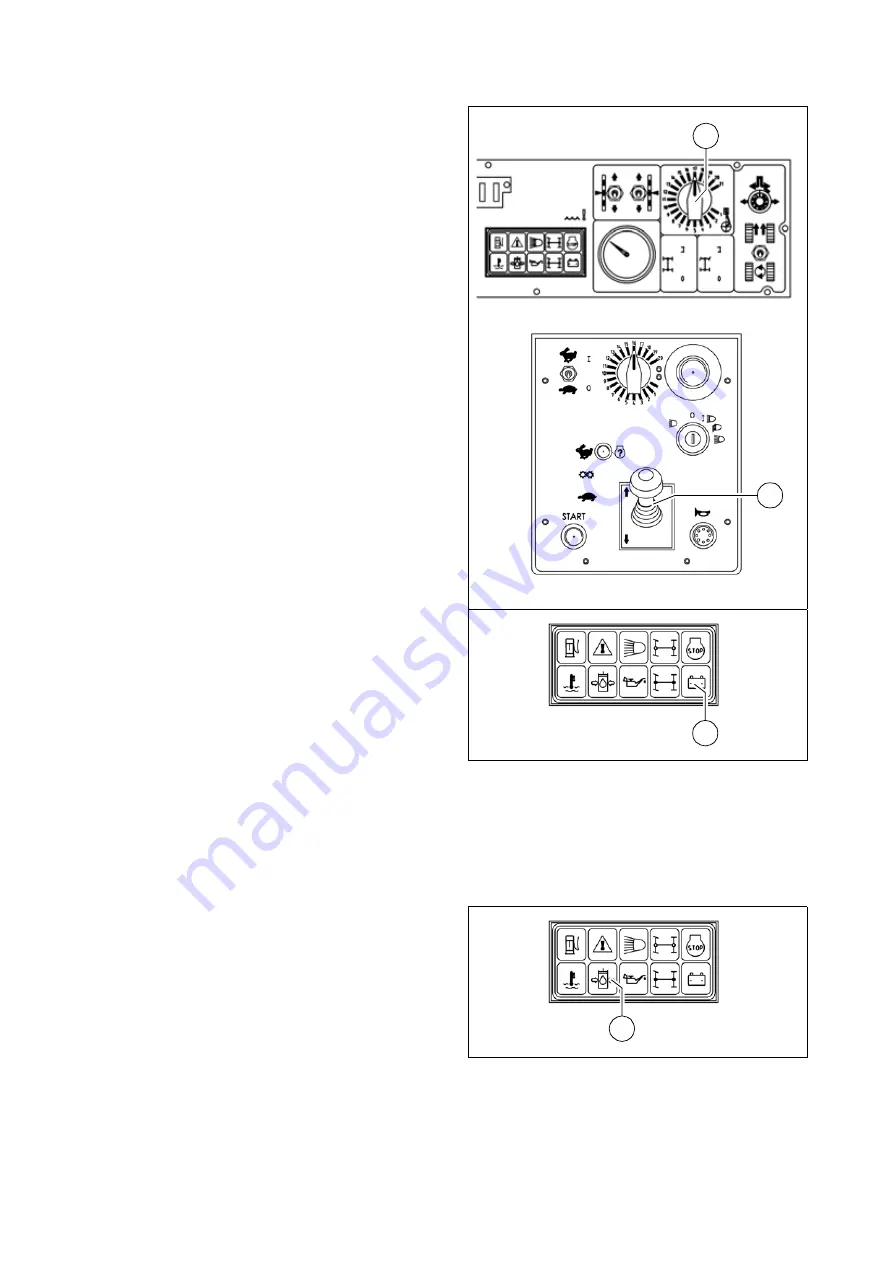

After starting

To increase the engine speed:

- Set the RPM regulator (1) to medium

speed.

- Switch the drive lever (2) to position 1

(slightly moving it from the central po-

sition).

m

Let the paver finisher warm up for ca. 5

minutes if the engine is cold.

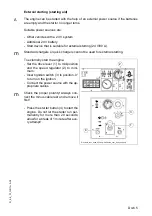

Indicator lamps

The following indicator lamps must be

observed under all circumstances:

For further possible faults, refer to the

operating instructions for the engine.

Battery charge indicator (1).

Must go out after starting when the en-

gine revs up.

m

Briefly rev up the engine when the lamp

does not go out or lights up during oper-

ation.

Switch off the engine and determine the cause for the malfunction if the lamp does

not go out.

For further possible malfunctions, refer to the section „Malfunctions”.

Oil pressure indicator lamp for the

traction drive (2)

- Must go out after starting.

m

If the lamp does not go out: Do not

switch on the traction drive! Otherwise,

the entire hydraulic system could be

damaged.

Element2_konv_Kette_635.bmp/Element3a_konv_Kette_635.bmp

1

2

Leuchtmodul_KONV_Kette_635.bmp

1

Leuchtmodul_KONV_Kette_635.bmp

2

Summary of Contents for DYNAPAC Svedala Demag DF 115 C

Page 2: ...VALUE QUALITY THE ORIGINAL Your Authorized Dynapac Dealer...

Page 10: ......

Page 18: ......

Page 20: ......

Page 44: ......

Page 58: ......

Page 62: ...D 1 4 4 D_1 4_01_GB fm 4 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Page 64: ...D 1 4 6 D_1 4_01_GB fm 6 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Page 96: ......

Page 120: ...D 4 6 24 D_4 6_01_GB fm 24 38 2 2 Error messages...

Page 121: ...D 4 6 25 D_4 6_01_GB fm 25 38...

Page 122: ...D 4 6 26 D_4 6_01_GB fm 26 38...

Page 123: ...D 4 6 27 D_4 6_01_GB fm 27 38...

Page 124: ...D 4 6 28 D_4 6_01_GB fm 28 38...

Page 125: ...D 4 6 29 D_4 6_01_GB fm 29 38 2 3 FMI codes...

Page 134: ......

Page 146: ...E 01 12 E_01_GB fm 12 18 3 Auger extension auger type II Auger_DEM bmp...

Page 152: ......

Page 154: ......

Page 157: ...F 3 0 1 F_3 0_01_GB fm 1 4 F 3 0 Maintenance Conveyor 1 Maintenance Conveyor...

Page 161: ...F 4 1 1 F_4 1_01_GB fm 1 8 F 4 1 Maintenance Auger 1 Maintenance auger sub unit...

Page 168: ......

Page 180: ......

Page 181: ...F 6 0 1 F_6 0_01_GB fm 1 8 F 6 0 Maintenance Hydraulic system 1 Maintenance hydraulic system...

Page 220: ......

Page 221: ...F 10 0 1 F_10 0_01_GB fm 1 6 F 10 0 Checks decommissioning 1 Tests check up cleaning stopping...

Page 226: ......