F 9.0 5

F_9

.0_

01_G

B.

fm

5-

8

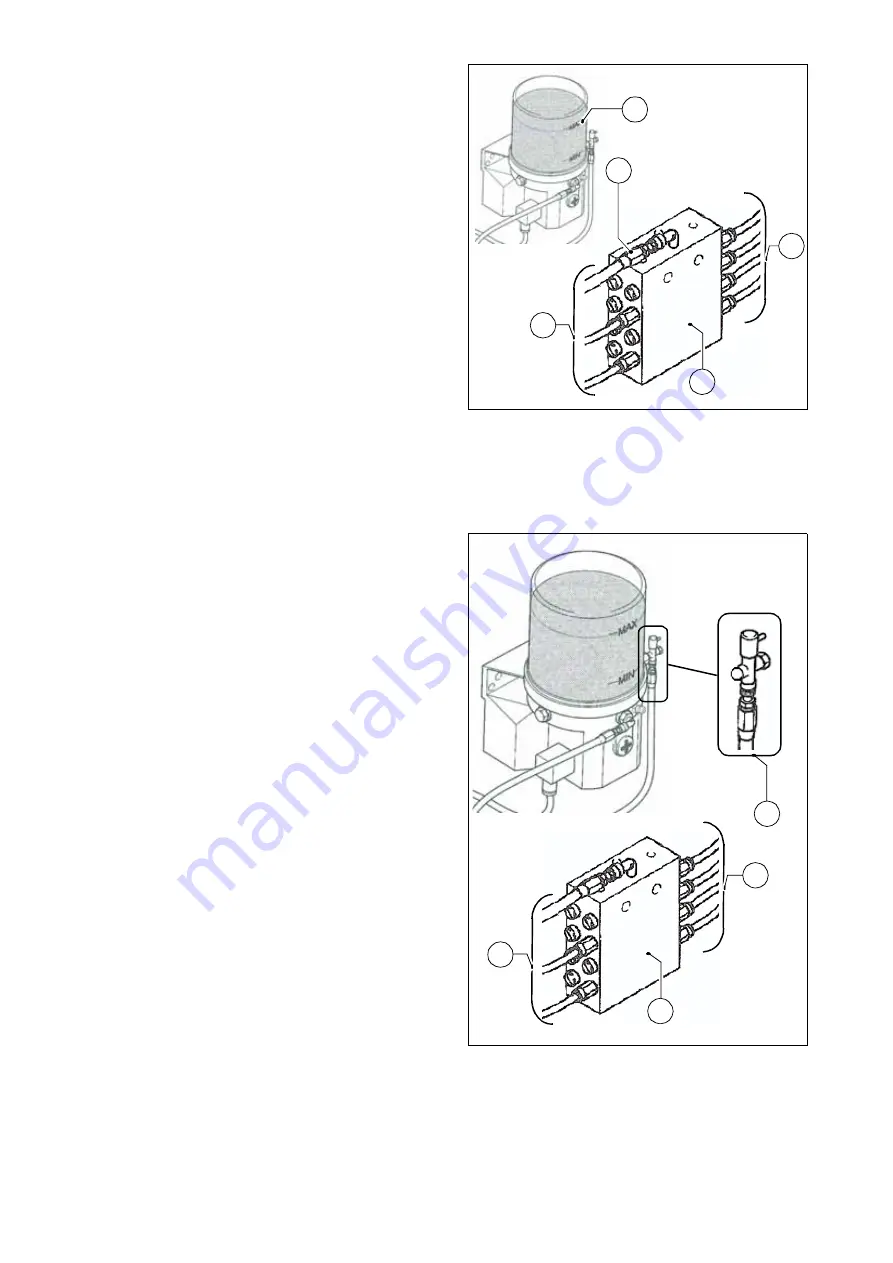

Vent the central lubrication unit

The venting of the lubrication system be-

comes necessary if the central lubrica-

tion unit was operated with an empty

lubrication tank.

- Untighten the main line (a) of the lu-

brication pump at the flow divider (b).

- Start the operation of the central lu-

brication unit with the refilled lubri-

cant tank (c).

- Leave the pump running until grease

is squeezed from previously untight-

ened main line (a).

- Retighten the main line (a) at the

flow divider.

- Remove all the manifold lines (d) at the flow divider.

- Reconnect again the manifold lines once lubricant is discharged through them.

- Check the tightness of all the connections and lines.

Check the pressure limiting valve

m

If lubricant is discharged at the pressure

limiting valve (a), this refers to failure in

the system.

The consumers receive not enough lu-

bricant.

- Disconnect the manifold lines (b),

which run from the flow divider (c) to

the consumers, one after the other.

- If lubricant is ejected from one of the

disconnected distribution pipes (b)

under pressure, then the clogging,

which led to the tripping of the pres-

sure limit valve, must be searched

for in this lubrication circuit.

- After correcting the fault and the re-

peated connection of all the lines,

check once again for lubricant dis-

charge from the pressure limit valve

(a).

- Check the tightness of all the con-

nections and lines.

Lincoln3.jpg/Lincoln4.jpg

a

b

c

d

d

Lincoln3.jpg/Lincoln4.jpg/Lincoln5.jpg

a

c

b

b

Summary of Contents for DYNAPAC Svedala Demag DF 115 C

Page 2: ...VALUE QUALITY THE ORIGINAL Your Authorized Dynapac Dealer...

Page 10: ......

Page 18: ......

Page 20: ......

Page 44: ......

Page 58: ......

Page 62: ...D 1 4 4 D_1 4_01_GB fm 4 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Page 64: ...D 1 4 6 D_1 4_01_GB fm 6 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Page 96: ......

Page 120: ...D 4 6 24 D_4 6_01_GB fm 24 38 2 2 Error messages...

Page 121: ...D 4 6 25 D_4 6_01_GB fm 25 38...

Page 122: ...D 4 6 26 D_4 6_01_GB fm 26 38...

Page 123: ...D 4 6 27 D_4 6_01_GB fm 27 38...

Page 124: ...D 4 6 28 D_4 6_01_GB fm 28 38...

Page 125: ...D 4 6 29 D_4 6_01_GB fm 29 38 2 3 FMI codes...

Page 134: ......

Page 146: ...E 01 12 E_01_GB fm 12 18 3 Auger extension auger type II Auger_DEM bmp...

Page 152: ......

Page 154: ......

Page 157: ...F 3 0 1 F_3 0_01_GB fm 1 4 F 3 0 Maintenance Conveyor 1 Maintenance Conveyor...

Page 161: ...F 4 1 1 F_4 1_01_GB fm 1 8 F 4 1 Maintenance Auger 1 Maintenance auger sub unit...

Page 168: ......

Page 180: ......

Page 181: ...F 6 0 1 F_6 0_01_GB fm 1 8 F 6 0 Maintenance Hydraulic system 1 Maintenance hydraulic system...

Page 220: ......

Page 221: ...F 10 0 1 F_10 0_01_GB fm 1 6 F 10 0 Checks decommissioning 1 Tests check up cleaning stopping...

Page 226: ......