D 1.4 17

D_1

.4_0

1_G

B.

fm

1

7

-2

2

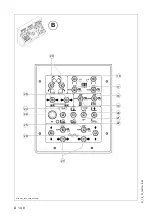

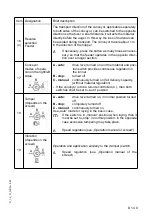

Item Designation

Brief description

35

has no function

36

Hydraulic oil ther-

mometer

Normal display up to 85 °C = 185 °F.

m

In case of higher temperature stop the machine, (set

drive lever to neutral position), and let the engine cool

at idling speed. Find the cause and eliminate the fault.

37

Alarm light (red)

„Water in the fuel“

This light is on, if the water separator of the fuel system has

established a too high water level.

m

In order to avoid the damage of the traction engine

drain the separated water immediately according to the

operation manual.

A

The fault is indicated together with the „Error message“

light.

38

Error message

(yellow)

It indicates that a fault has occurred in the traction engine. De-

pending on the type of the fault the operation of the machine

can be continued temporarily, or in case of a major fault it

must be stopped immediately to prevent further faults.

All the faults shall be eliminated as soon as possible!

A

The error message can be queried using button (13).

A

After the ignition is turned on, the light is on for a few

seconds for check-up.

39

High beam head-

light control lamp

(blue)

It is on, when the high beam headlight is switched on (at the

ignition switch).

f

Avoid blinding the oncoming traffic!

40

Not used

41

Stopping the en-

gine

It is on if the engine cannot be started (e.g. the emergency

stop button was depressed).

A

In such a case see Chapter „Operating failures“.

42

Indicator light of

engine tempera-

ture (red)

It is lit on, when the engine temperature is too high.

m

The output of the engine drops automatically. (Further

travel remains possible). Stop the paver finisher, (set

drive lever to neutral position), and let the engine cool

at idling speed. Find the cause and if necessary elimi-

nate it (see Chapter „Operating Faults“). Upon cooling

down to normal temperature, the engine will work

again at full capacity.

A

The fault is indicated together with the „Error message“

light.

Summary of Contents for DYNAPAC Svedala Demag DF 115 C

Page 2: ...VALUE QUALITY THE ORIGINAL Your Authorized Dynapac Dealer...

Page 10: ......

Page 18: ......

Page 20: ......

Page 44: ......

Page 58: ......

Page 62: ...D 1 4 4 D_1 4_01_GB fm 4 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Page 64: ...D 1 4 6 D_1 4_01_GB fm 6 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Page 96: ......

Page 120: ...D 4 6 24 D_4 6_01_GB fm 24 38 2 2 Error messages...

Page 121: ...D 4 6 25 D_4 6_01_GB fm 25 38...

Page 122: ...D 4 6 26 D_4 6_01_GB fm 26 38...

Page 123: ...D 4 6 27 D_4 6_01_GB fm 27 38...

Page 124: ...D 4 6 28 D_4 6_01_GB fm 28 38...

Page 125: ...D 4 6 29 D_4 6_01_GB fm 29 38 2 3 FMI codes...

Page 134: ......

Page 146: ...E 01 12 E_01_GB fm 12 18 3 Auger extension auger type II Auger_DEM bmp...

Page 152: ......

Page 154: ......

Page 157: ...F 3 0 1 F_3 0_01_GB fm 1 4 F 3 0 Maintenance Conveyor 1 Maintenance Conveyor...

Page 161: ...F 4 1 1 F_4 1_01_GB fm 1 8 F 4 1 Maintenance Auger 1 Maintenance auger sub unit...

Page 168: ......

Page 180: ......

Page 181: ...F 6 0 1 F_6 0_01_GB fm 1 8 F 6 0 Maintenance Hydraulic system 1 Maintenance hydraulic system...

Page 220: ......

Page 221: ...F 10 0 1 F_10 0_01_GB fm 1 6 F 10 0 Checks decommissioning 1 Tests check up cleaning stopping...

Page 226: ......