5

35

_DF115C_DF

135C_O

M

M

_

CO

N_02_G

BI

VZ.

fm

5-

8

E01

Set-up and modification ......................................................... 1

1

Special notes on safety .............................................................................. 1

2

Auger ......................................................................................................... 2

2.1

Height adjustment ...................................................................................... 2

2.2

Auger crossbeam installed in a fixed position ............................................ 2

2.3

Mechanical adjustment with ratchet (optional) ........................................... 3

2.4

In case of hydraulic adjustment (option) .................................................... 3

2.5

Auger extension, auger type I .................................................................... 5

2.6

Mounting extension parts ........................................................................... 6

2.7

Mounting support tube extensions ............................................................. 7

2.8

Installing tunnel plates ............................................................................... 8

2.9

Installing additional braces ......................................................................... 9

2.10

Auger mounting chart for ø 310 mm auger .............................................. 10

2.11

Auger mounting chart for ø 380 mm auger .............................................. 11

3

Auger extension, auger type II ................................................................. 12

3.1

Mounting extension parts ......................................................................... 13

3.2

Auger modification plan. .......................................................................... 15

4

Screed ...................................................................................................... 17

5

Electrical connections .............................................................................. 17

5.1

Remote controls ....................................................................................... 17

5.2

Grade control ........................................................................................... 17

5.3

Auger limit switches ................................................................................. 17

5.4

Working lights .......................................................................................... 17

F1.0

Maintenance ............................................................................ 1

1

Notes regarding safety ............................................................................... 1

F2.3

Maintenance overview ............................................................ 1

1

Maintenance review ................................................................................... 1

F3.0

Maintenance - Conveyor ........................................................ 1

1

Maintenance - Conveyor ............................................................................ 1

1.1

Maintenance intervals ................................................................................ 2

1.2

Points of maintenance ............................................................................... 3

Chain tightness of the conveyor (1) ....................................................... 3

The drive of conveyor (to the left/to the right) (2) ................................... 4

F4.1

Maintenance - Auger ............................................................... 1

1

Maintenance - auger sub-unit .................................................................... 1

1.1

Maintenance intervals ................................................................................ 2

1.2

Points of maintenance ............................................................................... 3

Auger - outer bearing (1) ....................................................................... 3

Auger planetary gear (2) ........................................................................ 3

Drive chain (3) of the transport augers .................................................. 4

Auger case (4) ....................................................................................... 6

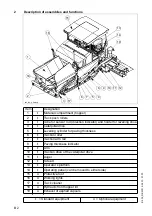

Summary of Contents for DYNAPAC Svedala Demag DF 115 C

Page 2: ...VALUE QUALITY THE ORIGINAL Your Authorized Dynapac Dealer...

Page 10: ......

Page 18: ......

Page 20: ......

Page 44: ......

Page 58: ......

Page 62: ...D 1 4 4 D_1 4_01_GB fm 4 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Page 64: ...D 1 4 6 D_1 4_01_GB fm 6 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Page 96: ......

Page 120: ...D 4 6 24 D_4 6_01_GB fm 24 38 2 2 Error messages...

Page 121: ...D 4 6 25 D_4 6_01_GB fm 25 38...

Page 122: ...D 4 6 26 D_4 6_01_GB fm 26 38...

Page 123: ...D 4 6 27 D_4 6_01_GB fm 27 38...

Page 124: ...D 4 6 28 D_4 6_01_GB fm 28 38...

Page 125: ...D 4 6 29 D_4 6_01_GB fm 29 38 2 3 FMI codes...

Page 134: ......

Page 146: ...E 01 12 E_01_GB fm 12 18 3 Auger extension auger type II Auger_DEM bmp...

Page 152: ......

Page 154: ......

Page 157: ...F 3 0 1 F_3 0_01_GB fm 1 4 F 3 0 Maintenance Conveyor 1 Maintenance Conveyor...

Page 161: ...F 4 1 1 F_4 1_01_GB fm 1 8 F 4 1 Maintenance Auger 1 Maintenance auger sub unit...

Page 168: ......

Page 180: ......

Page 181: ...F 6 0 1 F_6 0_01_GB fm 1 8 F 6 0 Maintenance Hydraulic system 1 Maintenance hydraulic system...

Page 220: ......

Page 221: ...F 10 0 1 F_10 0_01_GB fm 1 6 F 10 0 Checks decommissioning 1 Tests check up cleaning stopping...

Page 226: ......