D 1.4 9

D_1

.4_0

1_G

B.

fm

9

-22

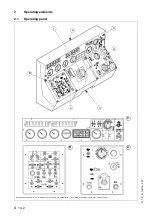

Item Designation

Brief description

16

(

o

)

Reverse

selection

Feeder

The transport direction of the conveyor, applicable separately

to both sides of the conveyor, can be switched to the opposite

direction so that over a short distance it retracts the material

directly before the auger. In this way the loss of material can

be avoided during transport. The conveyor travels about 1 m

in the direction of the hopper.

A

If necessary, press the button as many times as neces-

sary, so that the feeder operates in the opposite direc-

tion over a longer section.

17

Conveyor

modes of opera-

tion on the right/left

sides

A - auto:

drive lever turned on and the material end posi-

tion switch provides continuous regulation in

the tunnel

B - stop:

turned off

C - manual:

continuously turned on (full delivery capacity,

(without material regulation)

- If the conveyor is to be remote controlled (

o

), then both

switches shall be set to „auto“ position.

18

Tamper

(depends on the

screed)

A - auto:

drive lever turned on, in normal position turned

off

B - stop:

completely turned off

C - manual:

continuously turned on

Use „auto“ mode for laying in the basic case.

m

If the switch is in „manual“ position when laying, then it

must be set to „stop“ in normal position. In the opposite

case excessive tampering may take place.

A

Speed regulation (see „Operation manual of screed“)

19

Vibration

(depends on the

screed)

Operation and application similarly to the (tamper) switch.

A

Speed regulation (see „Operation manual of the

screed“).

B

C

A

A

B

C

A

B

C

Summary of Contents for DYNAPAC Svedala Demag DF 115 C

Page 2: ...VALUE QUALITY THE ORIGINAL Your Authorized Dynapac Dealer...

Page 10: ......

Page 18: ......

Page 20: ......

Page 44: ......

Page 58: ......

Page 62: ...D 1 4 4 D_1 4_01_GB fm 4 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Page 64: ...D 1 4 6 D_1 4_01_GB fm 6 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Page 96: ......

Page 120: ...D 4 6 24 D_4 6_01_GB fm 24 38 2 2 Error messages...

Page 121: ...D 4 6 25 D_4 6_01_GB fm 25 38...

Page 122: ...D 4 6 26 D_4 6_01_GB fm 26 38...

Page 123: ...D 4 6 27 D_4 6_01_GB fm 27 38...

Page 124: ...D 4 6 28 D_4 6_01_GB fm 28 38...

Page 125: ...D 4 6 29 D_4 6_01_GB fm 29 38 2 3 FMI codes...

Page 134: ......

Page 146: ...E 01 12 E_01_GB fm 12 18 3 Auger extension auger type II Auger_DEM bmp...

Page 152: ......

Page 154: ......

Page 157: ...F 3 0 1 F_3 0_01_GB fm 1 4 F 3 0 Maintenance Conveyor 1 Maintenance Conveyor...

Page 161: ...F 4 1 1 F_4 1_01_GB fm 1 8 F 4 1 Maintenance Auger 1 Maintenance auger sub unit...

Page 168: ......

Page 180: ......

Page 181: ...F 6 0 1 F_6 0_01_GB fm 1 8 F 6 0 Maintenance Hydraulic system 1 Maintenance hydraulic system...

Page 220: ......

Page 221: ...F 10 0 1 F_10 0_01_GB fm 1 6 F 10 0 Checks decommissioning 1 Tests check up cleaning stopping...

Page 226: ......