MD Series

6. Explanation of the Screen

6-3

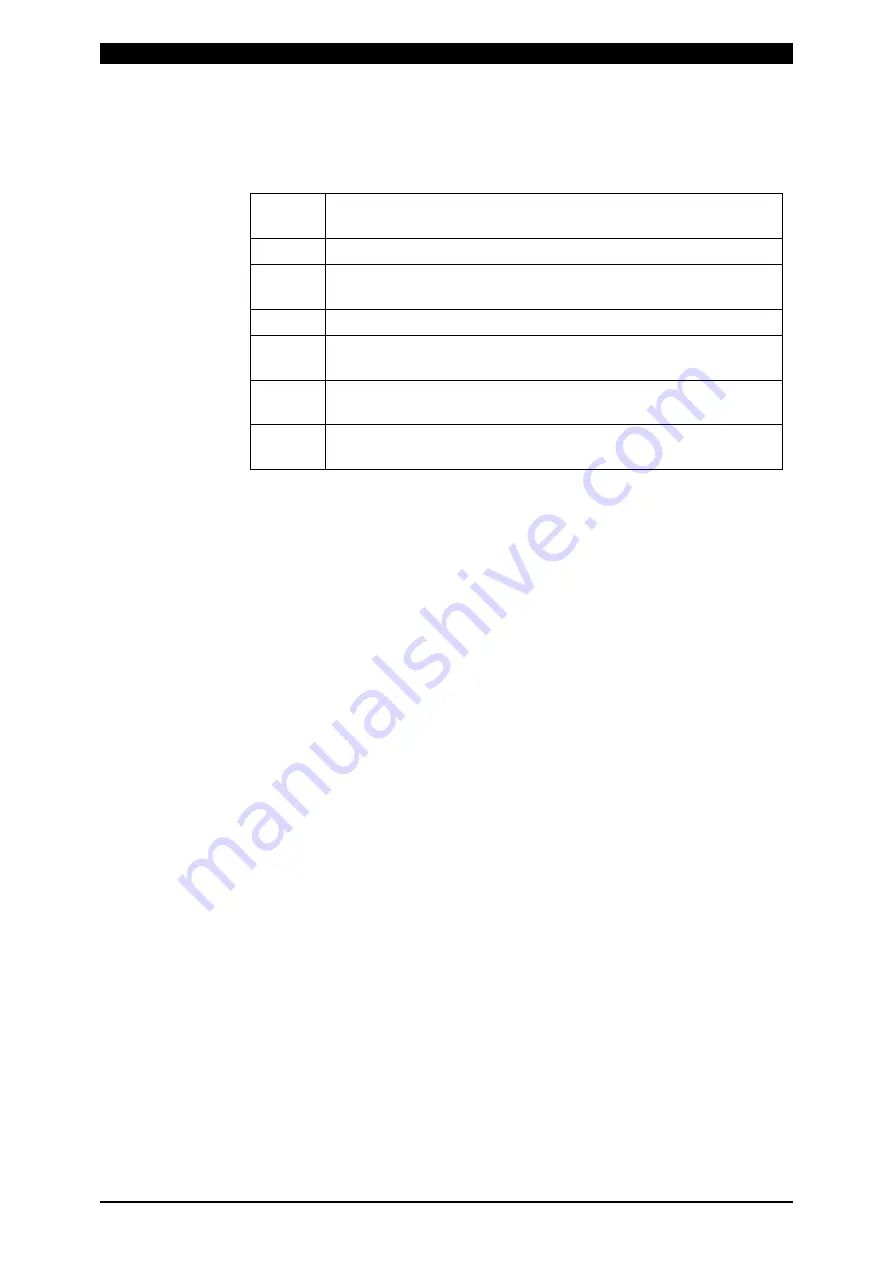

(b) TIME

Time period of each movement in welding is set in the unit of ms.

Refer to

5. (5) Timing Chart

for the relation of each period.

SQ

Time required until appropriate force is applied to the

workpiece.

WE1

Time during which WE1 welding current is applied.

COOL

Time during which welding current is stopped and the

workpiece is cooled.

WE2

Time during which WE2 welding current is applied.

HOLD

Time during which the workpiece is held after the welding

current has been applied.

↗

(*1)

Upslope (gradual increase in welding current) time.

Set it for WE1 and WE2 respectively.

↘

(*1)

Downslope (gradual decrease in welding current) time.

Set it for WE1 and WE2 respectively.

*1: When the welding portion except upslope and downslope is short

(there is not so much of a difference between the weld time (WE1

and WE2) and the time of [u downslope]), the set current

value and the monitored average value may be different. The

difference between the set value and the monitored value varies

depending on the rise rate of current.

The monitored interval can be set in MONITOR FIRST TIME. (Refer

to

(6)

⑮

MONITOR FIRST TIME

.)

(c) CURR

(*2)

Control current value. WE1 and WE2 are set, respectively.

When CONTROL on the STATUS screen is set to CURR, VOLT is not

displayed.

Also, when CONTROL is set to VOLT, CURR is not displayed.

(d) VOLT

(*2)

Control voltage value. WE1 and WE2 are set, respectively.

When CONTROL on the STATUS screen is set to CURR, VOLT is not

displayed.

Also, when CONTROL is set to VOLT, CURR is not displayed.

*2: Set the current value for welding so that the current flows within the

range of 10% to 100% of the maximum current value. The current

value can be checked on the MONITOR screen.

Summary of Contents for MD Series

Page 111: ......