4 - 103

ENG

TRANSMISSION, SHIFT CAM AND SHIFT FORK

EC4H4810

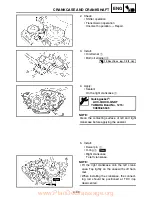

Shift fork, shift cam and segment

1. Inspect:

• Shift fork

1

Wear/damage/scratches

→

Replace.

2. Inspect:

• Shift cam

1

• Segment

2

Wear/damage

→

Replace.

3. Check:

• Shift fork movement

Unsmooth operation

→

Replace shift

fork.

NOTE:

For a malfunctioning shift fork, replace not only

the shift fork itself but the two gears each adja-

cent to the shift fork.

EC4H5000

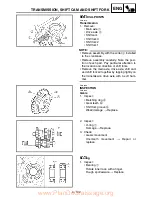

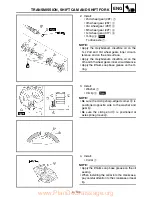

ASSEMBLY AND INSTALLATION

Transmission

1. Install:

• 5th pinion gear (27T)

1

• 3rd pinion gear (21T)

2

• Collar

3

• 4th pinion gear (24T)

4

• 2nd pinion gear (16T)

5

To main axle

6

.

NOTE:

• Apply the molybdenum disulfide oil on the

4th and 5th pinion gears inner circumference

and on the end surface.

• Apply the molybdenum disulfide oil on the

2nd and 3rd pinion gears inner circumfer-

ence.

www.PlanDeGraissage.org

Содержание WR250FR 2002

Страница 1: ...LIT 11626 16 48 WR250FR 5UM 28199 10 OWNER S SERVICE MANUAL www PlanDeGraissage org...

Страница 2: ...www PlanDeGraissage org...

Страница 5: ...www PlanDeGraissage org...

Страница 12: ...MEMO www PlanDeGraissage org...

Страница 118: ...3 53 INSP ADJ BATTERY INSPECTION AND CHARGING Charging method using a variable voltage charger www PlanDeGraissage org...

Страница 119: ...3 54 INSP ADJ BATTERY INSPECTION AND CHARGING Charging method using a constant voltage charger www PlanDeGraissage org...

Страница 143: ...4 21 ENG 9 Install Clamp 1 Refer to CABLE ROUTING DIAGRAM section in the CHAPTER 2 1 CARBURETOR www PlanDeGraissage org...