Control system

7-16

5.

Check the thermo switch for continuity

when the specified temperatures are

reached. Replace if out of specification.

6.

Install the thermo switch. See “Cylinder

block and electrical part” (5-67).

7.

Connect the thermo switch coupler.

Thermo sensor check

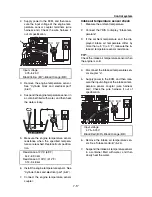

1.

Disconnect the thermo sensor coupler “a”.

2.

Supply power to the ECM, and then mea-

sure the input voltage at the thermo sensor

coupler terminals (wire harness end).

Check the wire harness if out of specifica-

tion.

3.

Remove the thermo sensor. See “Muffler”

(5-16).

4.

Suspend the thermo sensor in a container

filled with water, and then slowly heat the

water.

5.

Measure the thermo sensor resistance

when the specified temperatures are

reached. Replace if out of specification.

6.

Install the thermo sensor. See “Muffler”

(5-16).

7.

Connect the thermo sensor coupler.

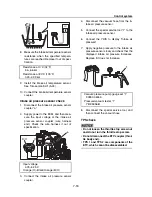

Engine temperature sensor check

1.

Disconnect the engine temperature sensor

coupler “a”.

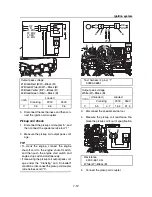

a. No continuity

b. Continuity

c. Continuity temperature

d. No continuity temperature

A. Temperature

B. Time

Continuity temperature

94–100 °C (201–212 °F)

No continuity temperature

80–94 °C (176–201 °F)

P

B

c

a

b

b

b

d

a

A

B

Input voltage

4.75–5.25 V

Black/Blue (B/L)–Black/Orange (B/O)

Resistance at 0°C (32°F)

24.0–37.1 k

Ω

Resistance at 100°C (212°F)

0.87–1.18 k

Ω

B/O

B/L

a

B

B

Содержание Waverunner VXS VX1800

Страница 1: ...SERVICE MANUAL WaveRunner VXS VX1800 F2W VXR VX1800A F2W F2W 28197 ZU 11 ...

Страница 12: ...How to use this manual 1 7 UP Upside YDIS Yamaha Diagnostic System Abbreviation Description ...

Страница 32: ...Technical tips 1 27 Trolling Neutral Neutral Reverse Engine stopped Condition Lever Reverse gate ...

Страница 40: ...Technical tips 1 35 MEMO ...

Страница 163: ...Oil separator tank and oil pan 5 72 3 4 4 4 4 4 9 4 1 5 6 10 11 7 2 3 8 ...

Страница 179: ...Crankcase connecting rod and piston 5 88 Crankcase bolt 1 10 Nm 1 0 kgf m 7 4 ft lb 12 11 10 4 2 6 8 9 3 1 5 7 1 ...

Страница 180: ...Crankcase connecting rod and piston 5 89 MEMO ...

Страница 196: ...6 15 Impeller drive shaft and impeller duct Impeller duct bolt 5 40 Nm 4 0 kgf m 29 5 ft lb 1 3 2 5 5 5 5 4 3 ...

Страница 204: ...6 23 Intermediate housing Intermediate housing bolt 2 17 Nm 1 7 kgf m 12 5 ft lb 1 2 3 ...

Страница 205: ...Intermediate housing 6 24 MEMO ...

Страница 251: ...Indication system 7 44 MEMO ...

Страница 253: ...8 Hull and hood Rear section 8 31 Spout installation 8 33 Reboarding step installation VXR 8 33 Deck and hull 8 34 ...

Страница 278: ...8 25 Exhaust system 6 Install the band Rubber hose clamp 2 3 5 Nm 0 35 kgf m 2 58 ft lb ...

Страница 290: ...Deck and hull 8 37 MEMO ...

Страница 312: ...Engine unit troubleshooting 9 21 MEMO ...

Страница 313: ...A Appendix Wiring diagram A 1 How to use the wiring diagram A 1 VXS VXR A 2 ...

Страница 317: ......

Страница 318: ...Mar 2015 CR E ...