YDIS

9-2

Function

1.

Diagnosis:

Each sensor’s status and each ECM diagnostic code or item is displayed. This enables

you to find malfunctioning parts and controls quickly. The diagnostic codes displayed are the same

as those described in “Diagnostic code and checking step” in this chapter.

2.

Diagnosis record:

Sensors that had been activated and ECM diagnostic codes that have been

recorded are displayed. This allows you to check the watercraft’s record of malfunctions. The diag-

nostic codes displayed are the same as those described in “Diagnostic code and checking step” in

this chapter.

3.

Engine monitor:

Each sensor status and the ECM data are displayed. This enables you to find

malfunctioning parts quickly. In addition, the data displayed using the Engine monitor function can

be displayed in a graph.

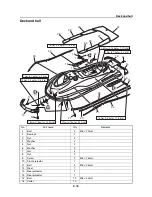

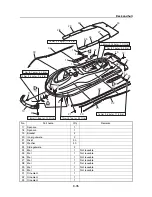

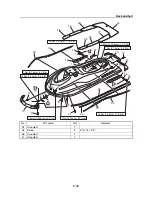

*1. RPS 1

*2. RPS 2

*3. Thermo sensor

4.

Stationary test:

Operation tests can be performed with the engine off.

*1. Operate fuel pump module

5.

Active test:

With the engine running, the ignition for each cylinder is dropped and the engine speed

is checked for changes to determine if the cylinder is malfunctioning. These tests can be performed

quickly.

6.

Logger graph:

Data stored in the ECM for the last 78 seconds (in 6-second intervals) is displayed

on a graph.

7.

ECM record graph:

When a malfunction occurs in the ETV system or APS system, 4 seconds (2

seconds before and after the malfunction) of recorded data is saved in the ECM. This data can be

displayed on a graph using the “ECM record data graph” of the Data logger function.

Engine speed

Battery voltage

No-wake mode switch

Intake air pressure

Fuel injection duration

Cruise assist set switch

TPS 1

Engine temperature

Cruise assist up switch

Throttle valve opening angle

Intake air temperature

Cruise assist down switch

TPS 2

Ex. manifold water tempera-

ture*3

Trim up switch

APS 1

Thermoswitch

Trim down switch

APS 2

Slant detection switch

Main relay

RPS main*1

Oil pressure switch

ETV relay

RPS sub*2

Engine start switch

Fuel pump relay

Atmospheric pressure

APS full close switch

Shift position angle

Ignition timing

Steering sensor

Activate ignition coil (#1–#4)

Activate injector (#1–#4)

Activate electric fuel pump*1

Engine speed

TPS

Intake air pressure

Battery voltage

Engine temperature

Oil pressure switch

Содержание Waverunner VXS VX1800

Страница 1: ...SERVICE MANUAL WaveRunner VXS VX1800 F2W VXR VX1800A F2W F2W 28197 ZU 11 ...

Страница 12: ...How to use this manual 1 7 UP Upside YDIS Yamaha Diagnostic System Abbreviation Description ...

Страница 32: ...Technical tips 1 27 Trolling Neutral Neutral Reverse Engine stopped Condition Lever Reverse gate ...

Страница 40: ...Technical tips 1 35 MEMO ...

Страница 163: ...Oil separator tank and oil pan 5 72 3 4 4 4 4 4 9 4 1 5 6 10 11 7 2 3 8 ...

Страница 179: ...Crankcase connecting rod and piston 5 88 Crankcase bolt 1 10 Nm 1 0 kgf m 7 4 ft lb 12 11 10 4 2 6 8 9 3 1 5 7 1 ...

Страница 180: ...Crankcase connecting rod and piston 5 89 MEMO ...

Страница 196: ...6 15 Impeller drive shaft and impeller duct Impeller duct bolt 5 40 Nm 4 0 kgf m 29 5 ft lb 1 3 2 5 5 5 5 4 3 ...

Страница 204: ...6 23 Intermediate housing Intermediate housing bolt 2 17 Nm 1 7 kgf m 12 5 ft lb 1 2 3 ...

Страница 205: ...Intermediate housing 6 24 MEMO ...

Страница 251: ...Indication system 7 44 MEMO ...

Страница 253: ...8 Hull and hood Rear section 8 31 Spout installation 8 33 Reboarding step installation VXR 8 33 Deck and hull 8 34 ...

Страница 278: ...8 25 Exhaust system 6 Install the band Rubber hose clamp 2 3 5 Nm 0 35 kgf m 2 58 ft lb ...

Страница 290: ...Deck and hull 8 37 MEMO ...

Страница 312: ...Engine unit troubleshooting 9 21 MEMO ...

Страница 313: ...A Appendix Wiring diagram A 1 How to use the wiring diagram A 1 VXS VXR A 2 ...

Страница 317: ......

Страница 318: ...Mar 2015 CR E ...