255

CHAPTER 8 - CFW-09 OPTIONS AND ACCESSORIES

At start-up, program Parameter

P202

– Type of Control = 4 (Vector with

Encoder) to operate the motor with incremental encoder speed feedback.

For more details about Vector Control operation refer to chapter 5.

The Expanded I/O Boards EBA and EBB are provided with externally powered,

isolated encoder output signals.

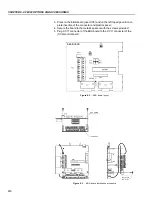

Figure 8.7

– Encoder cable

Encoder Connector***

A

A

H

A

B

B

I

B

C

Z

J

Z

D

+VE

F

COM

E

NC

G

red

blue

yellow

green

pink

white

brown

grey

cable shield

Connector XC9

Descripition

3

A

2

A

Encoder Signals

1

B

9

B

8

Z

7

Z

4

+VE

Power Supply*

6

COM

0 V Reference**

5

Ground

12 V

differential

(88C20)

Encoder

Max. Recommended lenght: 100 m (300 ft)

CFW-09 EBA or EBB Board

Connector XC9 (DB9 - Male)

* Power supply voltage 12 Vdc / 220 mA for encoder.

** Referenced to ground via 1

F in parallel with 1 k

*** Valid pin position with encoder HS35B models from Dynapar. For other encoder modules,

check the correct connection to meet the required sequence.

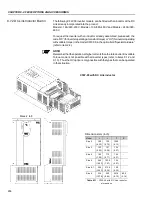

Connector XC8

Descrition

3

A

Encoder Signals

2

A

1

B

Line Driver

differential

9

B

(88C30)

Average high level

8

Z

current: 50 mA

7

Z

4

+V*

Power Supply*

0 V Refrence

6

COM 1*

5

Ground

Connector XC8 (DB9 Female)

*For on external power supply: 5 V to 15 V

Consumption: 100 mA @ 5 V, outputs not included.

Note:

Optionally, the external power supply can also be connected via:

XC4:19 and XC4:20 (EBA) or

XC5:19 and XC5:20 (EBB)

CFW-09 EBA or EBB Board

Figure 8.8

– Encoder signals repeater output

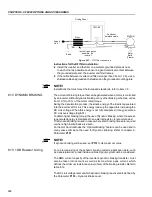

NOTE!

The max. permitted encoder frequency is 100 kHz.

9

6

5

1

Sequence of the encoder signals:

Motor running clockwise.

B

t

A

t

NOTE!

There is no internal power

supply for XC8 at EBA or EBB board.