Checking the boiler water temperature sensor, cylinder tem-

perature sensor or the flow temperature sensor for the low

loss header

1.

Boiler water temperature sensor:

Pull the leads from boiler tempera-

ture sensor

A

and check the resis-

tance.

Cylinder temperature sensor: Pull

plug

%

from the cable harness on

the control unit and check the resis-

tance.

Flow temperature sensor: Pull plug

"X3" from the control unit and check

the resistance across terminals

"X3.4" and "X3.5".

Repairs

(cont.)

77

Troubleshooting

5692

536

GB

Содержание Vitoplus 300

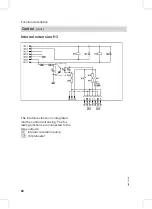

Страница 99: ...A1 Main PCB A2 Power supply unit Connection and wiring diagrams external connections 99 Designs 5692 536 GB ...

Страница 103: ...Parts lists cont 103 Parts lists 5692 536 GB ...

Страница 104: ...Parts lists cont 104 Parts lists 5692 536 GB ...

Страница 105: ...Parts lists cont 105 Parts lists 5692 536 GB ...

Страница 106: ...Parts lists cont 106 Parts lists 5692 536 GB ...

Страница 107: ...Parts lists cont 107 Parts lists 5692 536 GB ...

Страница 109: ...Service Service Service Service Commissioning service reports cont 109 Commissioning service reports 5692 536 GB ...

Страница 111: ...Service Service Service Service Commissioning service reports cont 111 Commissioning service reports 5692 536 GB ...

Страница 113: ...Service Service Service Service Commissioning service reports cont 113 Commissioning service reports 5692 536 GB ...

Страница 119: ...119 5692 536 GB ...