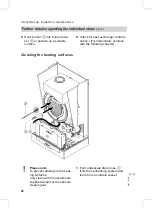

Filling the heating system

1.

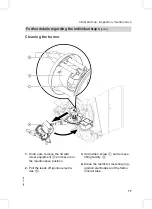

Check the inlet pressure of the dia-

phragm expansion vessel.

2.

!

Please note

Unsuitable fill water

increases the level of depos-

its and corrosion and may

lead to boiler damage.

&

Thoroughly flush the entire

heating system prior to fill-

ing it with water.

&

Only use fill water of pota-

ble quality.

&

Soften fill water harder

than 3.58 mmol/l.

&

An anti-freeze additive sui-

table for heating systems

can be added to the fill

water.

Drain the heating system via boiler

fill & drain valve

A

. (minimum sys-

tem pressure > 0.8 bar).

Note

If the control unit has not been

switched ON prior to filling the sys-

tem, then the servomotor of the

changeover valve will still be in its

central position, and the system will

be completely filled.

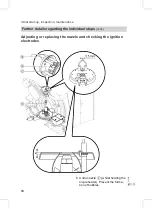

3.

If the control unit had already been

switched ON before filling began:

Start the control unit and in code 1,

set coding address "2F:2" (see

page 38).

The display shows "Filling"

The diverter valve is in its central

position.

Further details regarding the individual steps

7

Initial start-up, inspection, maintenance

5692

536

GB

Содержание Vitoplus 300

Страница 99: ...A1 Main PCB A2 Power supply unit Connection and wiring diagrams external connections 99 Designs 5692 536 GB ...

Страница 103: ...Parts lists cont 103 Parts lists 5692 536 GB ...

Страница 104: ...Parts lists cont 104 Parts lists 5692 536 GB ...

Страница 105: ...Parts lists cont 105 Parts lists 5692 536 GB ...

Страница 106: ...Parts lists cont 106 Parts lists 5692 536 GB ...

Страница 107: ...Parts lists cont 107 Parts lists 5692 536 GB ...

Страница 109: ...Service Service Service Service Commissioning service reports cont 109 Commissioning service reports 5692 536 GB ...

Страница 111: ...Service Service Service Service Commissioning service reports cont 111 Commissioning service reports 5692 536 GB ...

Страница 113: ...Service Service Service Service Commissioning service reports cont 113 Commissioning service reports 5692 536 GB ...

Страница 119: ...119 5692 536 GB ...