2.

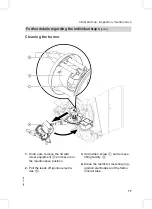

Insert a new LE nozzle

E

(whilst

holding the oil preheater).

Select the nozzle in accordance

with the details on page 13.

!

Please note

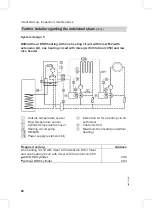

Only use nozzles marked

"V"

(on the hexagon) (see

Fig.).

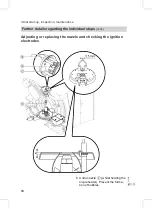

3.

Insert rifling facility

D

as far as

possible. Align ignition electrodes

B

in accordance with the drilled

holes towards the cable entries.

Install the oil burner nozzle cen-

trally in the restrictor.

4.

Secure Allen screw

C

of the rifling

facility. Check nozzle gap "a".

!

Please note

An incorrectly adjusted noz-

zle gap "a" can result in irre-

gular operation of the burner

and even a fault shutdown.

Rated output

kW

12.9/19.3

16.1/23.5

Nozzle gap "a"

(see page 18)

mm

3.0

+0.2/-0.3

1.5

+0.2/-0.3

Further details regarding the individual steps

(cont.)

19

Initial start-up, inspection, maintenance

5692

536

GB

Содержание Vitoplus 300

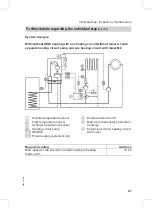

Страница 99: ...A1 Main PCB A2 Power supply unit Connection and wiring diagrams external connections 99 Designs 5692 536 GB ...

Страница 103: ...Parts lists cont 103 Parts lists 5692 536 GB ...

Страница 104: ...Parts lists cont 104 Parts lists 5692 536 GB ...

Страница 105: ...Parts lists cont 105 Parts lists 5692 536 GB ...

Страница 106: ...Parts lists cont 106 Parts lists 5692 536 GB ...

Страница 107: ...Parts lists cont 107 Parts lists 5692 536 GB ...

Страница 109: ...Service Service Service Service Commissioning service reports cont 109 Commissioning service reports 5692 536 GB ...

Страница 111: ...Service Service Service Service Commissioning service reports cont 111 Commissioning service reports 5692 536 GB ...

Страница 113: ...Service Service Service Service Commissioning service reports cont 113 Commissioning service reports 5692 536 GB ...

Страница 119: ...119 5692 536 GB ...