21

2. Maintenance and repairs by the customer

1) Replacing the oil in the oil-sealed rotary vacuum pump and oil diffusion

pump.

2) Replacing the element in the oil mist trap (sold separately).

3) Replacing the O-rings (except for the oil-sealed rotary vacuum pump)

4)

Cleaning the feed through collar and inside the glass bell jar.

Please contact us for any maintenance other than those listed above.

3. Removing, maintaining and installing equipment

3-1 Oil-sealed rotary vacuum pump

1) Tools needed: 8mm spanner×1 +screwdriver×1

2) Removal

・

Make sure all equipment is turned off.

・

Make sure the primary power is disconnected.

・

Remove the vacuum hose by pulling it towards you.

・

disconnect the motor wiring connectors (3 places) by pulling them to

the left or right.

Disconnect the ground lead from the mounting frame.

・

Remove the vibration-proof rubber nuts. (4 places)

・

Get two people to lift the motor and front cover, and remove the main

body of the pump.

・

Remove the vibration-proof rubber. (4 places)

3) Replace the oil

See the separate oil-sealed rotary vacuum pump user manual.

4) Attachment

・

Attach the vibration-proof rubber. (4 places)

・

Get two people to lift the motor and front cover, and reinstall the

pump.

・

Attach the motor wiring connectors. (3 places)

(Match up the wiring numbers, 1-1, 2-2 and 3-3)

If the wiring numbers do not match up, the pump will rotate in the

opposite direction.

・

Attach the ground lead.

・

Attach the vibration-proof rubber nuts. (4 places)

・

Attach the vacuum hose.

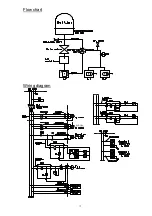

Vacuum hose

RP1

RP2

Motor wiring connector

Содержание VPC-1100

Страница 16: ...7 Layout of the switches handle and operation lever...

Страница 17: ...Flow chart Wiring diagram GLD 202A...