16

2. Inspecting the device before use

Inspection

The fixing clip at either end of the hoist’s wire

rope should be inspected daily to make sure

they have not come loose.

May cause the glass bell jar to fall.

Warning

Inspection

Make sure the hoist’s weight and the glass bell

jar cover’s eyebolt have not come loose.

May cause the glass bell jar to fall.

3. Using the exhaust system

3-1 Preparation

1) RP VENT Three-way valve main valve

CLOSE

2) All switches on the operating panel

OFF

3) If using an ionization vacuum gauge, attach the probe to the feed through collar’s

gauge port.

3-2 Operation

Exhaust system warm up

1) Your breaker

ON

Receiving light on main breaker

Should light up

2) Main breaker

ON

3) Cooling water

ON

4) RP1, RP2

ON

5) Three-way valve

FORE

6) Pirani vacuum gauge 10Pa or less DP ON

7) Liquid nitrogen

Pump in

8) DP warming up completes in 15 minutes.

Note

The amount of liquid nitrogen pumped in

Maximum intake 3.2 L (Including evaporated quantity)

Vapor Approx. 0.3L/h (At maximum intake)

If 3.2L is used, will remain effective for approx. 10 hours.

When all of the liquid nitrogen has evaporated, desorption of the trapped condensed

gas will take approximately 30 minutes, during which time the pressure will be reduced.

This is not a malfunction. Completely close the main valve to prevent the inside of the

bell jar from being contaminated.

Содержание VPC-1100

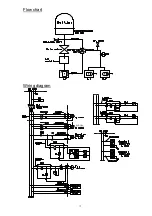

Страница 16: ...7 Layout of the switches handle and operation lever...

Страница 17: ...Flow chart Wiring diagram GLD 202A...