F

Use

protective

equipment

Wear a dusk mask and gloves when cleaning the thin film

of the feed through collar of the bell jar.

The thin film can turn into a fine dust and may be inhaled.

Do not

attempt alone

The glass bell jar weighs approximately 13 kg. It should

only be installed or removed by at least two people.

Risk of accidents or back pain.

Warning

Inspection

The fixing clip and eye bolt at either end of the hoist’s wire

rope should be inspected daily to make sure they have

not come loose.

May cause the bell jar to fall.

Periodic

replacements

The oil mist trap element (sold separately) should be

replaced every six months to one year.

If the element becomes clogged, exhaust resistance can build up and

cause oil leakage from the shaft seal or damage to the oil level

gauge.

Follow all

regulations

Waste oil used in the pump must be disposed of in

accordance with all relevant laws and regulations.

Please handle waste oil in accordance with the laws and regulations.

If anything is unclear, please contact us directly.

Caution

Prohibited

Do not modify this product using any parts other than the

standard optional parts provided by our company.

We will not be responsible for any consequences.

Caution

Check

labeling

Warning labels are attached to the following locations:

1)

bell jar cover

2)

main valve handle

3)

hoist brace

4)

liquid nitrogen trap

5)

rough pipe

6)

upper right side of the electrode switch

Please contact us if the labels become dirty and difficult to read, or

begin to peel off.

Maintenance, Repair and Disposal

Warning Labels

Содержание VPC-1100

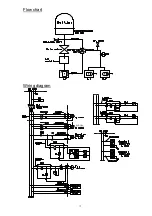

Страница 16: ...7 Layout of the switches handle and operation lever...

Страница 17: ...Flow chart Wiring diagram GLD 202A...