Engine Maintenance

9-13

The most common cause of fuel system problems is contamination. It cannot be stressed enough that the fuel must be clean,

fuel tanks must be free from contaminants, and the fuel filter must be changed regularly. Any time that the fuel system is opened

up, all possible precautions must be taken to keep dirt from entering the system. This means all fuel lines should be capped when

open. The work should be done in a relatively clean area, if possible, and the work should be completed in the shortest time

possible.

The injection nozzles must be tested (and repaired if necessary) at least every 3,000 hours in accordance with EPA 40 CFR

Part 89. Normal conditions are considered to be the use of clean high quality fuel, no used oil blending, and regular

maintenance of the fuel system according to the Maintenance Inspection Schedule. Refer to the TK270, TK370, and TK376

Overhaul Manual TK 53163 for injection nozzle testing and repair procedures.

Thermo King recommends that any major injection pump or nozzle repairs be done by a quality diesel injection service

specialty shop. The investment in equipment and facilities to service these components is quite high. Therefore, this equipment

is not found in most repair shops.

The following procedures can be done under field conditions:

• Bleeding air from the fuel system

• Maintenance involving the fuel tank and filter system

• Engine speed adjustments

• Electric transfer pump replacement or repair (10 psig [69 kPa] pump with diesel filter)

• Injection line replacement

• Pump timing

• Nozzle spray pattern testing and adjustment

• Minor rebuilding of nozzles.

Bleeding the Fuel System

The fuel system will have to have the air bled out if the engine runs out of fuel, if repairs are made to the fuel system, or air

gets into the system for any other reason.

MAKE SURE to keep the fuel tank vent open. If the vent becomes clogged, a partial vacuum develops in the tank, and this

increases the tendency for air to enter the system.

Proceed as follows:

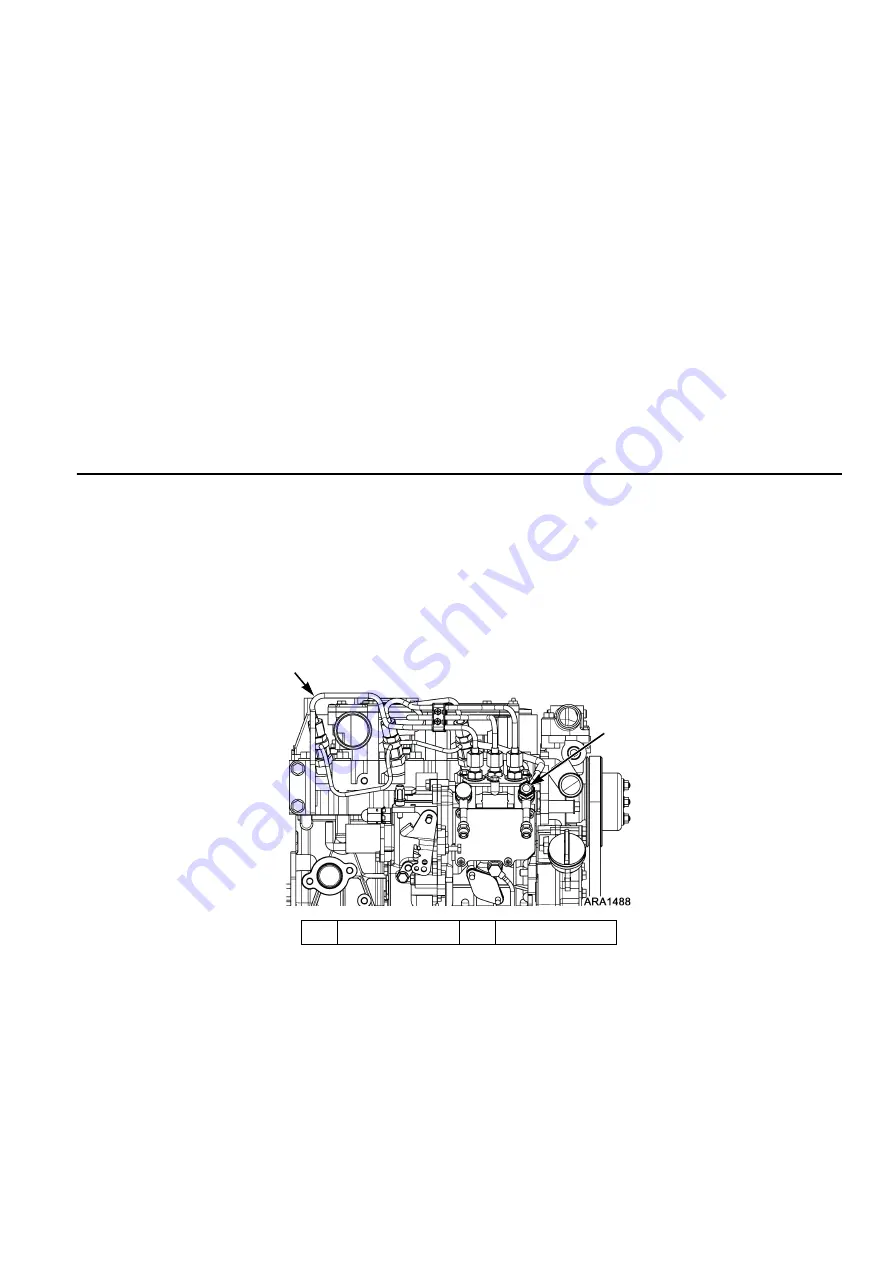

1. Loosen the bleeder screw on the return fuel fitting of the injection pump.

2. Turn on the electric fuel pump. The electric fuel pump is energized when the

O

N

key is pushed. Tighten the bleeder screw on

the injection pump when clear flow of fuel appears.

NOTE: At initial starT-up, open the bleeder screw at the injection pump and bleed fuel until a clear

flow is noted.

3. Loosen the injector lines on the injection nozzles.

4. Crank the engine until fuel appears at the nozzles. Tighten the injector lines, and start the engine.

NOTE: Fuel will not appear at the nozzles by merely running the electric pump. The engine must be

cranked.

1.

Injector Line

2.

Bleeder Screw

Injection Pump

2

1

Содержание T-1000R

Страница 14: ...Safety Precautions 2 6 Warning Decals 2e24151g0 ...

Страница 18: ...Specifications 3 4 ENGINE CLUTCH Engagement 600 100 RPM Dynamic Torque 66 fT lb 89 5 N m minimum 1600 RPM ...

Страница 34: ...Maintenance Inspection Schedule 4 10 ...

Страница 57: ...Unit Description 5 23 Purge Mode UT Series 1 3 4 5 2 ...

Страница 67: ...Unit Description 5 33 Zone 1 Cool and Zone 2 Cool UT SPECTRUM Units ...

Страница 69: ...Unit Description 5 35 Purge Mode UT SPECTRUM Units ...

Страница 71: ...Unit Description 5 37 Zone 1 Cool and Zone 2 Heat UT SPECTRUM Units ...

Страница 72: ...Unit Description 5 38 ...

Страница 74: ...Diesel Electric Menu 6 28 Adjust Brightness 6 29 Time 6 30 ...

Страница 120: ...Operating Instructions Standard HMI 7 18 ...

Страница 152: ...Engine Maintenance 9 14 T Series Fuel and Oil System Components TK 376 ...

Страница 154: ...Engine Maintenance 9 16 T Series Fuel and Oil System Components TK 270 ...

Страница 156: ...Engine Maintenance 9 18 UT Series Fuel System Components AMA768 ...

Страница 172: ...Engine Maintenance 9 34 T Series Engine Mounting Components for 2 Cylinder Engine ...

Страница 184: ...Engine Maintenance 9 46 ...

Страница 238: ...Refrigeration Maintenance 10 54 ...

Страница 246: ...Clutch Maintenance 11 8 ...

Страница 258: ...Structural Maintenance 12 12 ...

Страница 264: ...Mechanical Diagnosis 13 6 ...

Страница 265: ...14 Electric Standby Diagnosis ...

Страница 268: ...Electric Standby Diagnosis 14 4 ...

Страница 269: ...15 Refrigeration System Diagnosis ...

Страница 272: ...Refrigeration System Diagnosis 15 4 ...

Страница 280: ...Remote Evaporators 16 8 ...

Страница 282: ...Wiring Diagrams and Wiring Schematics 17 2 ...