ST2516 Series Operation Manual

20

NOTE: Before measurement, it is necessary to warm up the instrument and the probe for about

half an hour. The temperature sensor should be placed to the DUT as close as possible but

cannot contact it. After the displayed result comes to be stable, you can read or record the

result.

3.6.2

Temperature conversion (∆t)

Temperature conversion (∆t)

: Basically, resistors have heat effect. Temperature conversion

represents the temperature difference between the resistor and the environment.

Formula:

2 (

1) (

)

1

R

t

k t

k ta

R

∆ =

+

−

+

∆

t is the temperature increment.

t1 is the temperature at the start of resistance measurement.

ta is the environment temperature.

R1 is the resistance at the start of contact.

R2 is the resistance after the display is stable.

K is the variance ration of the environment temperature coefficient when the conductor is at

0

℃

.

For example

When R1 is 2

00mΩ,

t1 is 20

℃, R2 is

210

mΩ, ta is 25

℃ and k is 235.

Δ

t

=

𝐑𝟐

𝐑𝟏

(k + t1) –(k + ta)=

𝟐𝟏𝟎

𝐱𝟏𝟎

−𝟑

𝟐𝟎𝟎

𝐱𝟏𝟎

−𝟑

(235 + 20) –(235+25)=7.75

℃

The temperature after the resistance is stable is calculated as the following formula:

𝑡

𝑅

=

ta +Δt = 25 +7.75 = 32.75

℃

Where, k =

1

α

t0

- t0, if

α

t0

= 3930ppm, k is 234.5

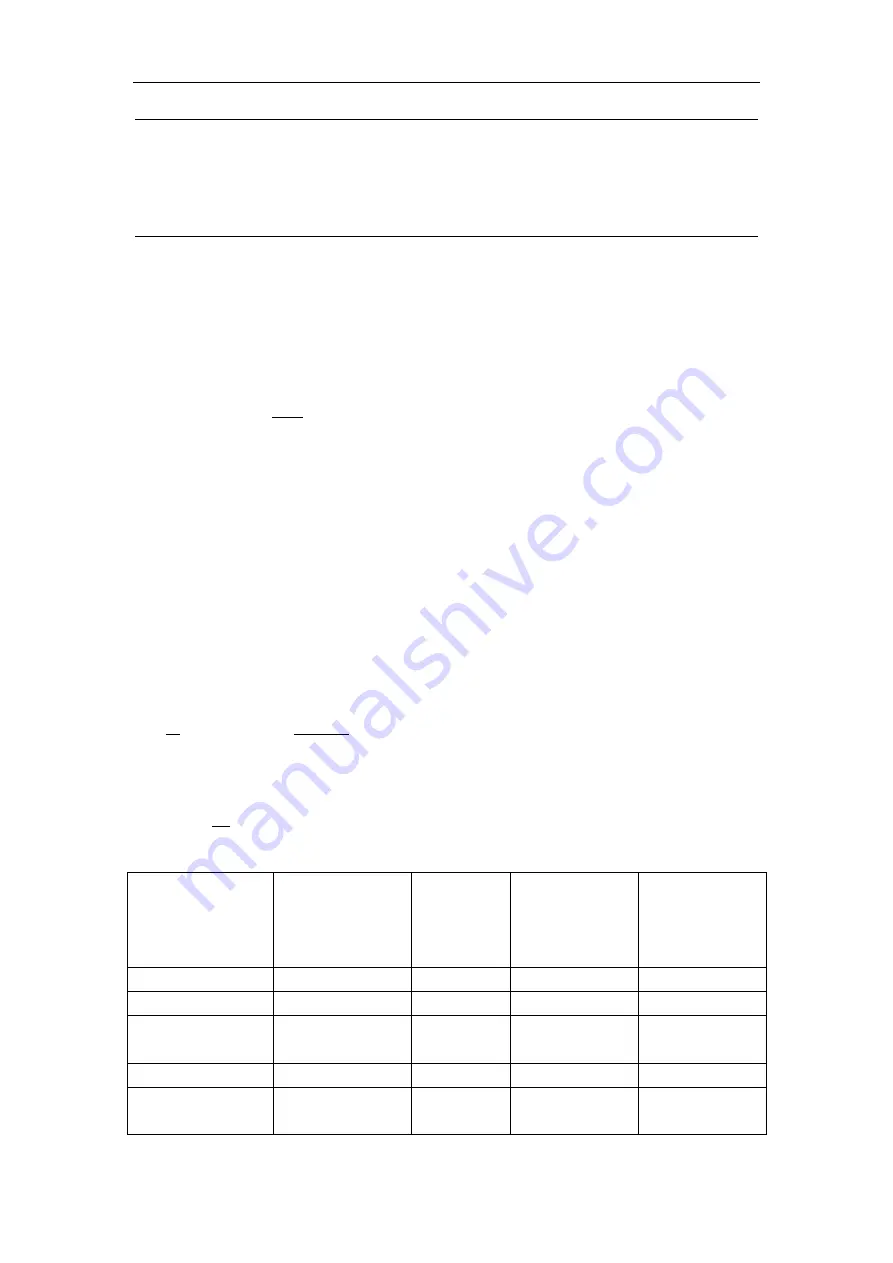

NOTE: Conductivity and temperature coefficient of metal and alloy

Metallic material

Metal

[%]

Material

density

(x

10

3

)

[kg/

m

3

]

Conductivity

Temperature

coefficient

(20

℃

)

[ppm]

Annealed copper

Copper>99.9

8.89

1.00 to 1.02

3810 to 3970

Hard-drawn copper Copper>99.9

8.89

0.96 to 0.98

3370 to 3850

Cadmium copper

Cadmium: 0.7 to

1.2

8.94

0.85 to 0.88

3340 to 3460

Silver copper

Silver: 0.03 to 0.1

8.89

0.96 to 0.98

3930

Chromium copper

Chromium: 0.4 to

0.8

8.89

0.40 to 0.50

0.80 to 0.85

20

30