7

SALICRU

• All power supply electrical cables have to be fixed to the equip-

ments and loads, interfaces, etc..., to immovable parts and in

the way to avoid step on it or go through them with an transport

medium or expose them to fortuitous pulls.

• Be careful to not wet it, because it is not waterproofed. Do not

allow entering any kind of liquids in, otherwise shutdown it im-

mediately and contact with the

(S.T.S.)

.

• If the enclosure of the equipment is in contact with liquids or

high density saline air accidentally, dry it with a soft and absor-

bent cloth quickly.

Check that no liquid has entered inside the unit and act accord-

ingly.

• To clean the equipment, wipe over a damp cloth and then dry it.

Avoid liquids sprinkling or spillage that could enter through the

slots or cooling grids, which may cause fire or electric shock.

Do not clean the equipments with products that could have al-

cohol, benzene, solvent or other inflammable substances, and

even if they are abrasive, corrosive, liquids or detergent.

• Never manipulate the equipment with wet hands.

• If it is observed that the UPS exhausts smoke or toxic gas, shut-

down it immediately and disconnect it from power supply. This

kind of fault can cause fire or electrical discharge. Contact with

our

(S.T.S.)

.

• Do not put either materials or parts over the equipment that

obstruct the correct visualization of the synoptic.

•

Before using the UPS for first time or after a long period

of time (6 months maximum), it has to be connected to

the power supply to charge the batteries for a minimum period

of time of 12 hours.

Although the equipment can operate with batteries discharged,

it has to be kept in mind the possible risk of mains fault during

the first operating hours, so the available back up time in the

UPS batteries, can be lower than the expected.

2.2.2. General safety warnings.

• All electrical connections and disconnections of cables from

the equipment, including the control ones, will be done with no

power supply and switches on rest position «O» or «Off».

•

Pay special attention to the labelling of the equipment

that warns about the «Electrical shock hazard», inside

the equipment there are dangerous voltages.

Do not open, dismantle or modify the equipment, if this action

is not stated in this document. To manipulate inside the equip-

ment for repairing is restricted to

qualified

staff only. In case of

maintenance or fault, consult to the closest

(S.T.S.)

.

A part from the implicit risk of electrical shock, any action that

make the modification, internal or external of the equipment

or just only the simple intervention inside of itself, which is not

stated in this document,

it can expire the warranty

.

• During the erection and commissioning operations is needed to

open the front door and some models is required to remove the

protection cover from terminals too.

Once the respective actions are finalised, leave the equipment as

it was, with the protection cover put back and front door closed.

• To shutdown the equipment completely, follow the instructions

in the start up and shutdown chapter.

Consult the documentation before doing any action. A

wrong manipulation over the switches can cause impor-

tant production losses and/or failures in the equipments.

•

Protection Earth cable of the UPS drives the leakage current

of the load devices. An isolated earth cable has to be in-

stalled as part of the circuit that supplies the equipment. Cross cable

section and its features will be the same as the power supply cables,

but with green colour with or without the yellow strip.

•

The protection earth must be connected to the frame or

metallic chassis of any electrical equipment, by means

of the foreseen terminal (in our case to the UPS, battery cabinet

when it is available and loads), assuring that it is done before

turning on the input voltage.

It is essential that cables that feed the loads have their respective

protection earth cable.

When branch circuits are made, i.e. by means of terminal strips,

it is essential to have a protection earth terminal in each one

of them.

• Check the quality and availability of the earth, it has to be between

the defined parameters by the local or national regulations.

•

During the normal UPS operation, the input power supply

cable can’t be disconnected, because the general protec-

tion earth cable of the own UPS and all loads connected at the

output will be disconnected too.

Due to the same reason, the general protection earth cable of

the building or switchgear panel that supplies the UPS will not be

disconnected.

• Cross cable sections used to supply the equipment and loads to be fed,

will be according to the nominal current stated in the nameplate label of

the equipment, and respecting the Low Voltage Electrotechnical Regu-

lations or standards of the country.

•

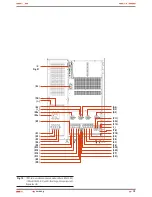

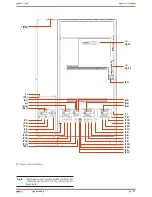

CUBE3+

equipments can be manufactured in four different

configurations of Input-Output:

Three phase - Three phase.

Three phase - Single phase.

Single phase - Three phase.

Single phase - Single phase.

For the correct operation of the UPS, it is needed the input Neu-

tral cable or in case of its missing, it has to be created by means

of an isolation transformer located between the power supply

and the equipment.

• The UPS doesn’t modify the input neutral regime at its output.

Do not earth the output neutral.

When, it is needed to modify the output neutral regime, an iso-

lation transformer has to be located between the loads and the

equipment.

•

In those models with separate bypass line, an isolation

transformer has to be located in any of both input lines

(rectifier input or static bypass), in order to avoid the direct con-

nection of the neutral of both lines through the internal wiring of

the equipment.

This is only applicable when the two power supplies come from

different lines, i.e.::

Two different electrical companies.

One electrical company and a generator, ...

• La The installation will have input protections sized to the cur-

rents of the equipment and stated in the nameplate label (RCD